-

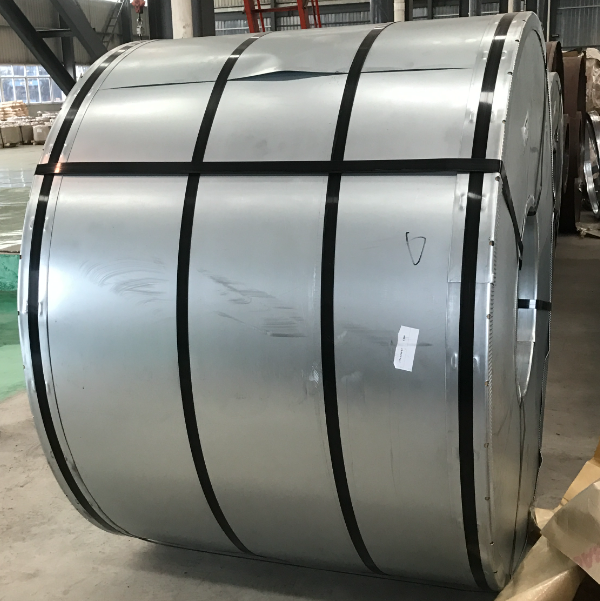

Custom Galvanized Steel Coil Z275

Galvanized steel coil Z275 is a type of steel sheet that has been coated with a layer of zinc on its surface.Z275: Indicates that the average grammage of the zinc layer is 275 g/m2.Galvanizing is a frequently used, economical and effective method of corrosion protection.Approximately 50% of the global production of zinc is utilized in this particular process.

-

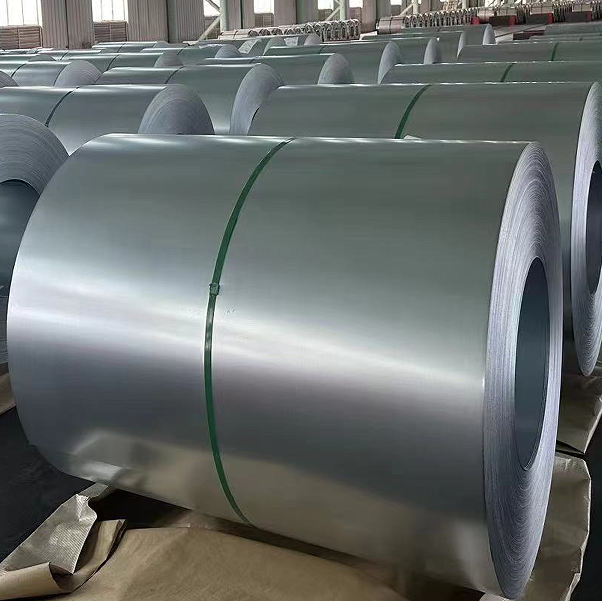

Hot Dipped Galvanized Steel Coil Dx51d

DX51D is a European standard. Hot dipped galvanized steel coil Dx51d involves the use of 51 raw materials that are equivalent to SGCC. The primary chemical components of these coils are as follows: C%≤0.07, Si%≤0.03, Mn%≤0.50, P%≤0.025, S%≤0.025, and Alt%≥0.020.

-

Color Coated Prepainted Steel Ppgi Coil Green

PPGI color prepainted galvanized steel coil green is a kind of steel plate with organic coating, with good corrosion resistance, bright colors, beautiful appearance, easy processing and molding and has the advantages of the original strength of the steel plate and lower cost and so on.

-

Magnesium-Aluminum-Zinc Coated Steel Sheets Coils

Zinc-aluminum-magnesium steel sheet in coil as a new type of material, with excellent corrosion resistance, good mechanical properties, long service life and other characteristics, in the production process of zinc, aluminum, magnesium and other elements, a wide range of applications, and has a broad prospect for future development.

-

Prepainted Galvanized Steel Coil Ppgi DX51D

Prepainted galvanized steel sheet in coil is a commonly used metal material with excellent corrosion resistance and good forming properties, so it is widely used in construction, transportation, electronics, etc. DX51D is a specification of galvanized sheet coil, in which “D” means galvanized sheet, “X ” indicates that the substrate is hot rolled sheet, “51″: serial number, no specific meaning, on behalf of the general use.

-

hot dipped galvalume steel coil sheet DX51D+AZ

DX51D+AZ is a grade of galvalume steel coil.The special coating structure gives it excellent corrosion resistance.

-

Galvanized Steel Strip DX51D

DX51D European standard galvanized steel strip is known as the guardian of steel against rust and corrosion. It is armed with a galvanizing process that gives the steel excellent corrosion resistance. It is used in a wide range of applications in the automotive, electrical and manufacturing sectors. Its high corrosion resistance is like a strong armor for steel, so that moisture and environmental factors can not erode its healthy body.

-

ZINC-ALUMINIUM-MAGNESIUM STEEL SHEET IN COILS JIS G3323

Zinc-aluminium-magnesium steel sheet in coil is an alloy material composed of three elements: zinc, aluminium and magnesium, which belongs to a new type of lightweight and high-strength material. The material has excellent mechanical properties and corrosion resistance, and the price is relatively low, it is one of the materials that have been widely used in recent years.

-

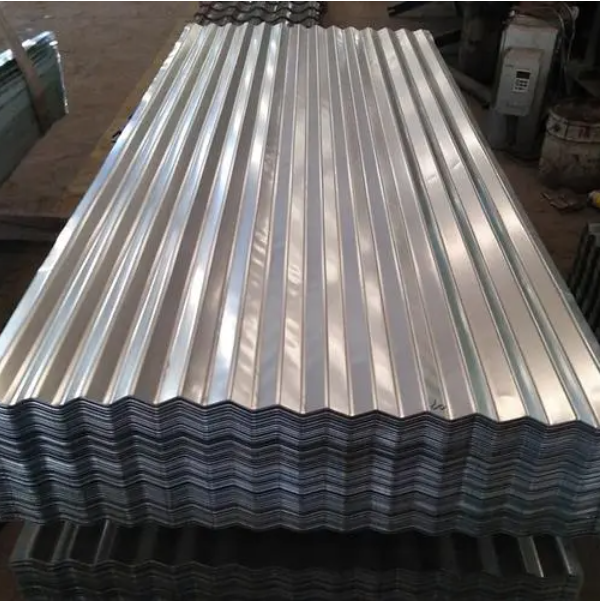

Corrugated Metal Roofing Sheet

Metal roofing refers to a roofing form that uses metal sheets as the roofing material and combines the structural layer and the waterproof layer into one.

Type: zinc plate, galvanized plate

Thickness:0.4~1.5mm

-

hot dipped galvanized corrugated steel sheets

Galvanized corrugated steel sheet is cold rolled continuous hot dip galvanized steel sheet and strip with a thickness of 0.25 to 2.5mm. It is widely used in construction, packaging, railway vehicles, agricultural machinery manufacturing and daily necessities.

-

red roofing sheets color coated prepainted steel ppgi coil

“Color-coated prepainted steel PPGI coil” refers to a novel building material that has recently been introduced. It is made of steel plate that undergoes a series of surface treatments and then one or more layers of organic coating and baking. Color-coated sheets find extensive application in various industries such as construction, furniture, electrical appliances, and transportation.

-

color coated corrugated roofing sheets red blue white green brown

Color coated corrugated sheets are a profiled board made of aluminum plate that is rolled and cold-bent into various corrugated shapes. These roofing sheets are commonly known as colored corrugated roofing sheets. They are lightweight, come in a range of colors and are easy to install. They have a long lifespan and are resistant to fire, earthquakes, and rain, requiring minimal maintenance.