Cold Rolled Steel Coil And Sheet

Cold Rolled Steel Coil

Cold rolled steel plates are steel plates produced through cold rolling processes, referred to as cold plates.

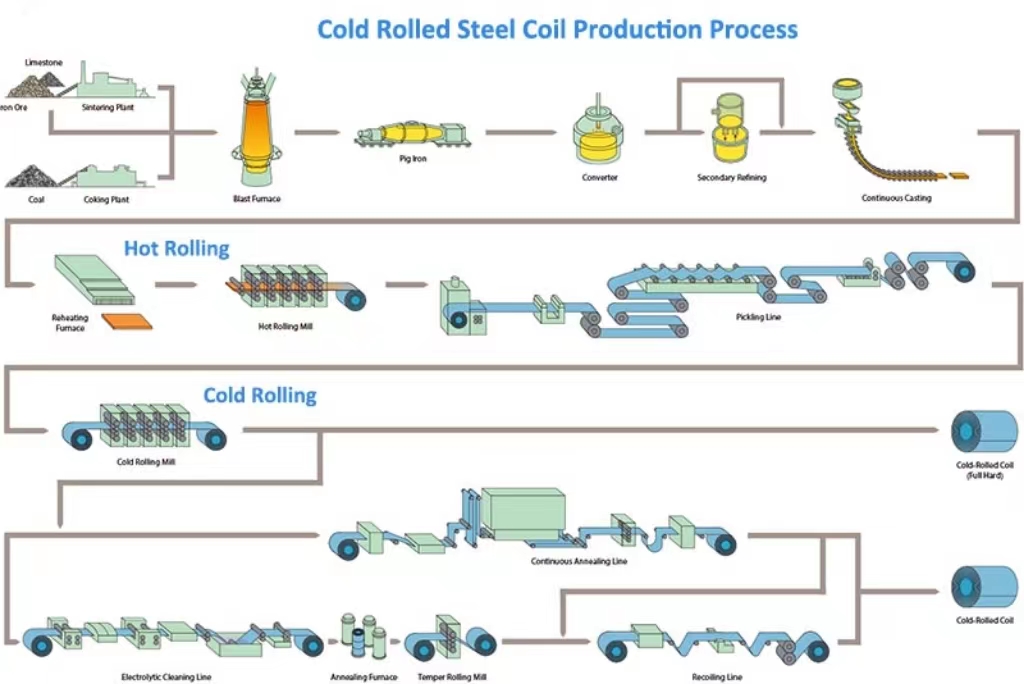

The thickness and width of cold rolled carbon steel plates are determined according to the equipment capacity of each factory and market demand. Cold rolling is processed and rolled on the basic of hot rolled coils. Generally speaking, it is a process of hot rolling -pickling-cold rolling.Cold Rolled Steel sheet can be divided into cold rolled steel coil with full hard and common steel cold rolled coil.

| standard | GB, JIS, EN, ASTM |

| Material | SPCC-1B, SPCC-1D,SPCC-SD, DC04, DC03, DC01 |

| Width | 800-1250mm |

| Thickness | 0.15-2.0mm |

| Elongation( annealing) | 30-40 percent |

| Tensile Strength | 345-420Rm/MPA |

| Hardness | HRBT1-T7 |

| Application | For short pitch precision roller chains(A series & B series), Walking tractor & rotovator chains, A & B series roller chains for combines, ZGS38 combines chains, rice harvester chains, S,C, A, CA type steel agricultural chains and so on. |

Cold rolling is processed and rolled on the basic of hot rolled steel in coils. Generally speaking, it is a process of hot rolling -pickling-cold rolling.

Firstly, full hard coil uses hot rolled coil as raw material, via pickling to remove iron dross and make continuous rolling, increase the intensity and hardness of full hard coil, which can be used as the simply deformed parts and the raw material of hot dipped galvanized coils; Secondly, common cold rolled sheet adopting continuous annealing or bell type annealing to eliminate hardening and rolling stress, meet the relevant criterion of biomechanical property, which is suitable for the further processing that uses cold rolled steel sheet as substrate, and then making high added value products. For instance, hot dipped galvanized steel sheets, color coated steel coil and stock resistant complex steel sheet etc, which enjoys the good quality of artistic and high anticorrosion.

Advantages of cold rolled steel plate:

1. Cold rolled carbon steel coils have product standards and uniform thickness, which can fully meet the requirements of high-precision tolerances.

2. Ultra thin strips that cannot be produced by hot rolling can be obtained, and the thickness can be less than 0.001mm.

3. The surface quality of cold rolled products is excellent, and there are no defects such as pitting and pressed oxide scale that often appear in hot-rolled coils. Moreover, coils with different surface roughness can be produced according to user requirements to facilitate the following process of processing.

4. The coil pitch of cold-rolled plates has excellent mechanical properties and process properties, high strength, low yield limit, and excellent deep drawing properties.

5. It can achieve high speed rolling and full continuous rolling, with high productivity.

Cold rolled coils are used for:

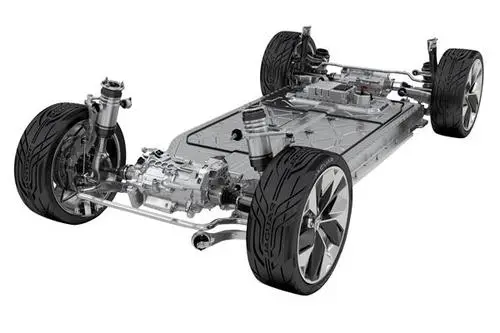

1. Manufacture of automobile parts: automobile chassis, doors, roofs, hoods, body structural parts and other components.

2. Manufacturing building structural parts, roofs, wall panels and other materials.

3. Manufacture various mechanical parts, such as gears, shafts, chains, etc.

4. Added steel: Cold rolled plates can be used as raw materials for electron microscopes, hot mirrors and other steel products, and added into various specifications of steel.

Inside package:Water proof paper + Inhibitor film

Outside package:Steel sheet cover + Steel edge protectors + Sufficient steel straps

Customized according to the need to develop different ways.

Our company has large warehouses all over China, with sufficient inventory and short delivery cycle. With many years of experience in exporting coiled materials, we have standard packaging and Transportation Standards for sheet materials shipping, so as to protect the safety of your goods in shipping in an all-round way. Applicable to container and bulk cargo.

Why choose Lishengda Trading Co?

1. Contract is honored and credit maintained.

2. Competitive price with excellent quality.

3. Professional exporting team.

4.Convenient transportation location.

5. Short shipment period.