Galvanized Steel Coils Sheets plates

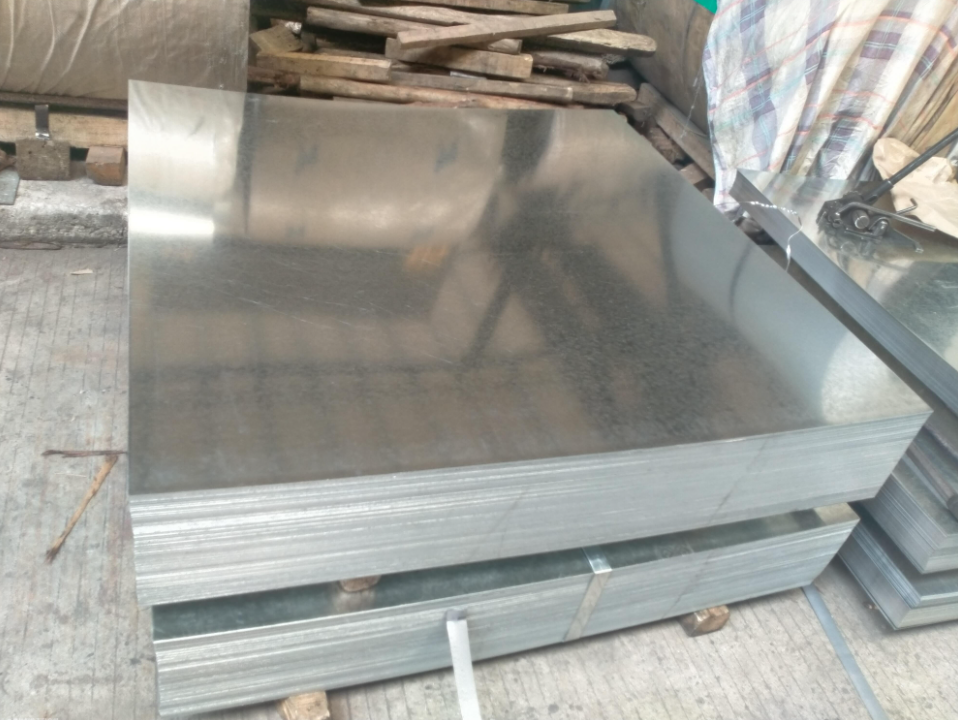

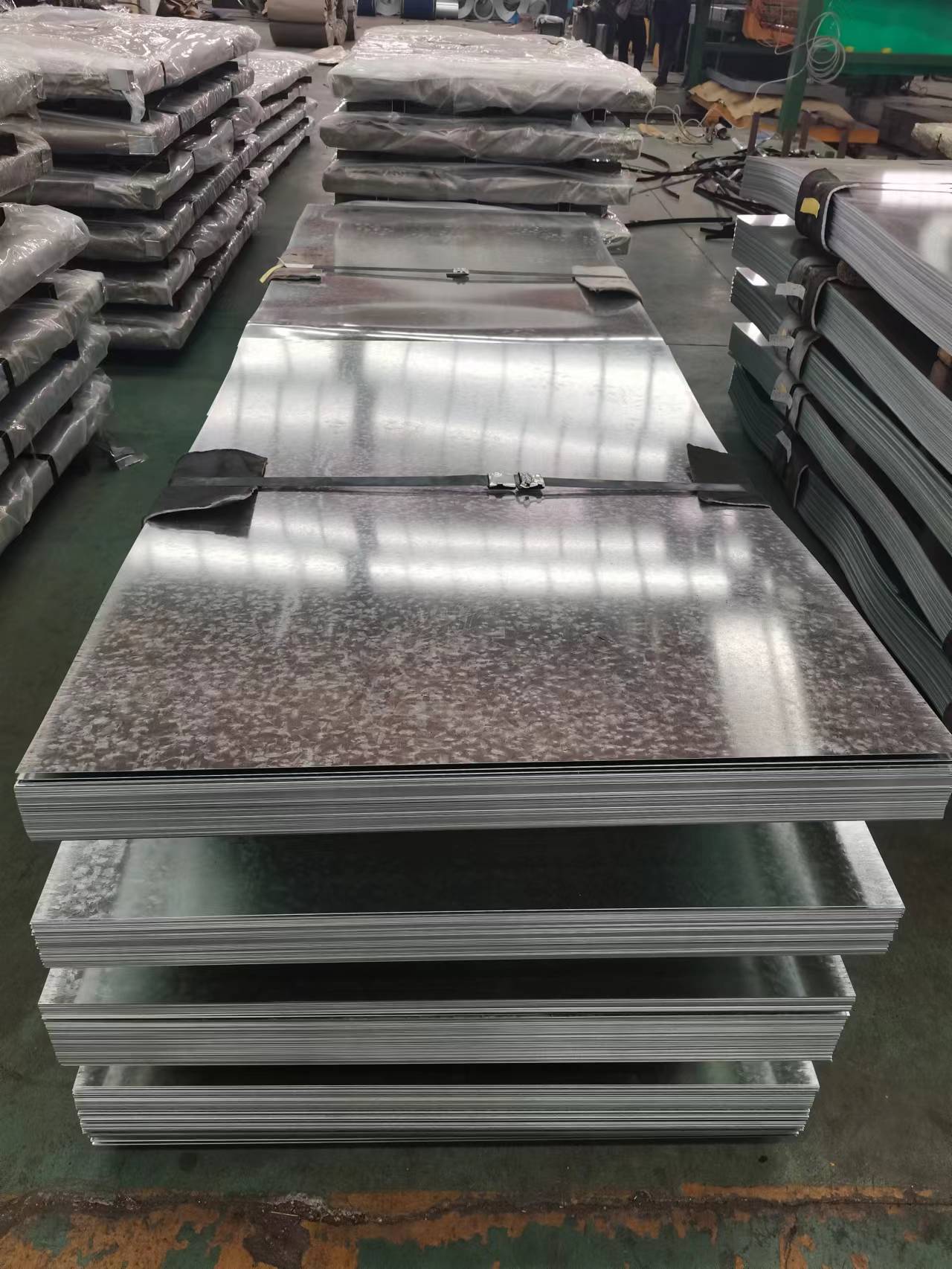

Galvanized Steel Plate

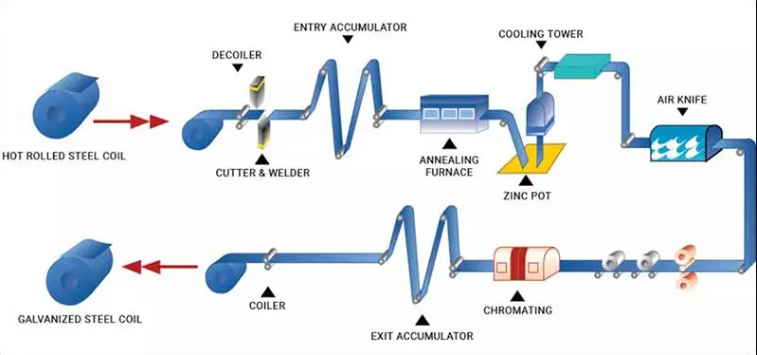

Galvanized steel plate coils are mainly produced by the continuous galvanizing process, that is, the rolled steel panels are continuously immersed in a plating bath containing molten zinc to make galvanized steel panels. This kind of steel plate is also made by the hot dip method, but it is heated to about 500°C immediately after coming out of the tank to form an alloy film of zinc and iron.

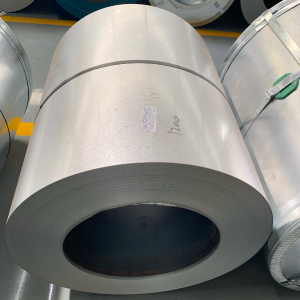

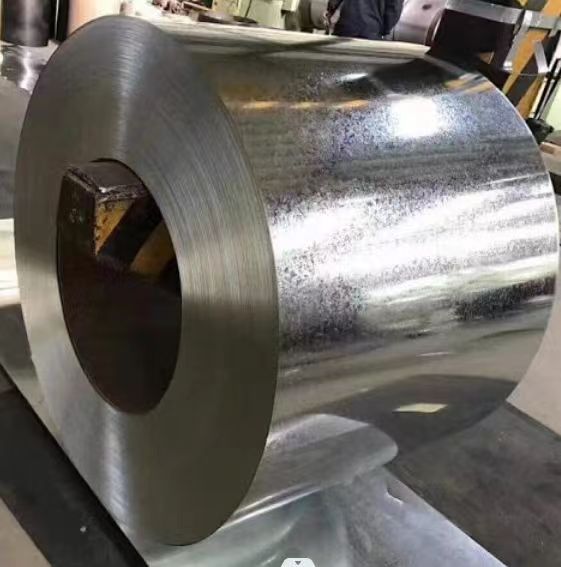

Galvanized Steel Coil

This kind of galvanized coil has good paint adhesion and weldability.Galvanized sheet plates can be used as galvanized base plates for color coated galvanized steel coils.

| Standards | GB/JIS/ASTM |

| Size range | Thickness 0.10-4.0mm, Width 500-1250mm |

| Zinc coating | 30-275g/m2 |

| Coil ID | 508mm&610mm |

| Surface | Chromated/Un-oiled/Dry |

| Spangle | Regular/Minimized/Big Spangle/Zero Spangle |

| Coil weight | 4-12mt |

| Material | SGCC, DX51D, SGCH |

| Application | Construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

| Packing | Standard Export packing(Plastic film in the first layer, second layer is Kraft paper. Third layer is galvanized sheet) |

Advantages of galvanizing: Galvanizing refers to coating the surface of color steel coils with a layer of zinc metal, which forms a corrosion-resistant protective layer through a chemical reaction. This processing method gives color steel coils the following important advantages:

1.Good corrosion resistance: The galvanized layer can effectively prevent the steel from coming into contact with oxygen, moisture and other substances in the environment, thereby reducing the corrosion rate of the steel and extending its service life.

2.Good anti-oxidation performance: The galvanized layer can form a dense oxide film under the action of oxygen, which further protects the steel.

3.Good weather resistance: The galvanized layer can remain stable under various climate conditions, is not affected by wind and rain, and is suitable for various outdoor environments.

Application

Galvanized Steel Sheets are widely used in the construction field due to their excellent performance. Here are some typical application areas:

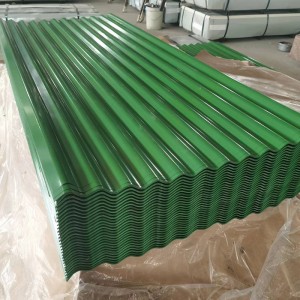

Roofing and walls: The corrosion resistance of galvanized steel coils makes it an ideal roofing and wall material, and can be used for covering decoration of residential buildings, commercial buildings, industrial plants and other buildings.

Cold storage and storage facilities: The antioxidant properties of galvanized steel coils make it an excellent performer in cold storage and storage facilities, effectively preventing rust and corrosion.

Transportation facilities: Galvanized coils are also often used in the construction of light buildings such as bus shelters, carports, parking lot awnings, etc. Their weather resistance and aesthetics are ideal.

Necessary maintenance and upkeep: Although galvanized coils have good corrosion resistance, they still require certain maintenance and upkeep during long-term use.

Common maintenance methods include regular cleaning, preventing scratches, and avoiding long-term immersion in water.

These simple maintenance measures can extend the service life of color steel coils and maintain their good appearance.

Inside: Anti-rust paper, plastic.

Outside: Steel inner and outside guard board, Circle Iron guard board for both side, outside iron guard board, 3 Radical Strapping and 3 Latitude Strapping.

We can also pack according to your requirement.