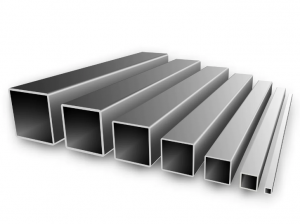

Mild Hollow Sections Square Steel Metal Tube Pipe

Square And Rectangular Steel Tube

Steel pipes have high compressive strength, superior to normal building materials such as wood and cement. Square hollow steel metal tube is widely used in large buildings and projects such as bridges and airports. Due to their excellent compressive strength, steel pipes can withstand overloaded weights and pressures, thus ensuring the safety and reliability of the project.

| Surface | Bare, Painted, Oiled, Galvanized and so on |

| Shape | Square. Rectangular |

| Size | 12*12mm to 600*600mm |

| Thickness | 0.6~40mm |

| Color | Clean, blasting and painting or as required |

| Advantages | High Strength,Resistant High Mechanical Stresses |

| Resistant to High Pressure,Resistant to High Temperature | |

| Good Formality,Reusablehaode |

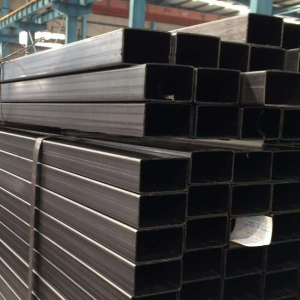

A rectangular or square tube is a steel pipe made of steel plate or strip after crimping and welding, generally .

Such as cold-formed square hollow section, cold-formed rectangular hollow section, hot-finish square hollow section, hot-finish rectangular hollow section, galvanized square pipe, galvanized steel pipe, pre-galvanized pipe, scaffolding steel pipe, seamless steel pipe, square hollow steel metal tube, welded steel pipe.

Types of Packaging:

Bundles (hexagonal)

Wooden Boxes

Crates (steel/wooden)

Special crates for Structural Hollow Sections with each radius separated

Packaging for Carbon Steel Seamless Pipe as per customer’s requirements

Square and rectangular steel tubes are in contact with the environment for a long time and are susceptible to oxidation and corrosion. However, with the development of advanced modern technology, new techniques for preventing corrosion of steel pipes are emerging. For example, spray coatings, hot-dip galvanising and electro-galvanising are techniques that can extend the service life of steel pipes so that they remain quite durable in harsh environments.

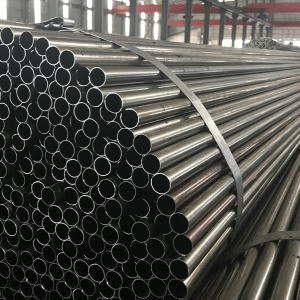

Compared with other construction materials, seamless steel pipes have high processing properties. They can be cut, bent, welded and spliced as needed to make components of different shapes and lengths. Because of their regular shape and high precision, steel pipes are more convenient and accurate in processing, shortening the working period and reducing costs.