Hot dip galvanizing, also known as galvanizing, is a method of immersing steel components in molten zinc to obtain a metal coating.Electro galvanizing is commonly known as "cold galvanizing" or "water galvanizing"; it uses electrochemistry, using a zinc ingot as an anode. The zinc atoms lose their electrons and become ions and dissolve into the electrolyte, while the steel material acts as an anode. At the cathode, zinc ions receive electrons from the steel and are reduced to zinc atoms that are deposited on the surface of the steel to achieve a process in which the coating forms a uniform, dense, and well-bonded metal or alloy deposition layer.This article will give you an in-depth explanation of the differences between the two.

1. Different coating thicknesses

The hot dip galvanized coating generally has a thicker zinc layer, about 40 μm or more, or even as high as 200 μm or more. The hot dip galvanized layer is generally 10 to 20 times that of the electroplated zinc layer. The electroplated zinc coating is very thin, about 3-15μm, and the coating weight is only 10-50g/m2.

2. Different galvanizing amounts

The galvanizing amount of hot dipped galvanized steel coils cannot be too small. Generally, the minimum is 50~60g/m2 on both sides and the maximum is 600g/m2. The galvanized layer of electro galvanized steel coils can be very thin, with a minimum of 15g/m2. However, if the coating is required to be thicker, the production line speed will be very slow, which is not suitable for the process characteristics of modern units. Generally, the maximum is 100g/m2. Because of this, the production of electro galvanized steel sheets is greatly restricted.

3. The coating structure is different

There is a slightly brittle compound layer between the pure zinc coating of the hot dip galvanized sheet and the steel plate matrix. When the pure zinc coating crystallizes, most of the zinc flowers are formed, and the coating is uniform and has no pores. The zinc atoms in the electroplated zinc layer are only precipitated on the surface of the steel plate, and are physically attached to the surface of the steel strip. There are many pores, which can easily cause pitting corrosion due to corrosive media. Therefore, hot dip galvanized plates are more resistant than electro galvanized plates corrosion.

4. Different heat treatment processes

Hot dipped galvanized steel sheets are generally made of cold hard plates and are continuously annealed and hot dip galvanized on the galvanizing line. The steel strip is heated for a short period of time and then cooled, so the strength and plasticity are affected to a certain extent. Its stamping performance is better than The same cold hard plate is different from the cold rolled steel plate after degreasing and annealing in a professional production line. Hot dipped galvanized steel sheets have lower production costs and wider application range, and have become the main variety in the galvanized sheet market. Electro galvanized steel sheets use cold rolled steel sheets as raw materials, which basically guarantees the same processing performance of cold rolled sheets, but its complex process also increases production costs.

5. Different appearance

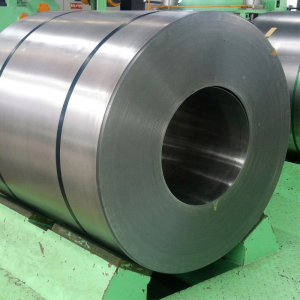

The surface of the hot dip galvanized layer is rough and bright, and in severe cases there are zinc flowers; the electro galvanized layer is smooth and gray (stained).

6. Different application scopes and processes

Hot-dip galvanizing is suitable for large components and equipment; hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is passed through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and chlorine. Zinc mixed aqueous solution tank for cleaning, and then sent to the hot dip plating tank.

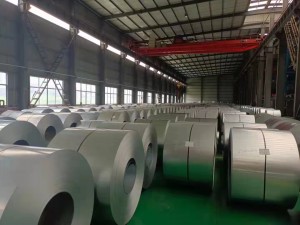

Hot dipped galvanized steel coil has good coverage, dense coating, and no dirt inclusions. It has the advantages of uniform coating, strong adhesion and long service life. Hot-dip galvanizing has better resistance to atmospheric corrosion of base metal iron than electro-galvanizing.

Galvanized steel sheets made by electroplating have good processing performance, but the coating is thin and the corrosion resistance is not as good as that of hot dipped galvanized steel sheets; the amount of zinc attached to electro galvanized steel coilis very small, and only the outer pipe wall is galvanized, while hot-dip galvanizing is both inside and outside.

Post time: Nov-17-2023