Cold rolled SPCC is a well known brand in the steel trade, and is often labeled as 'cold rolled plate', 'general use', etc.However, friends may not know that there are also ‘1/2 hard’, ‘annealed only’, ‘pitted or smooth’, etc. in the SPCC standard. I don't understand questions like "What is the difference between SPCC SD and SPCCT?"

We still say that in the steel trade, "if you buy the wrong thing, you will lose money." The editor will analyze it in detail for you today.

SPCC Brand Traceability

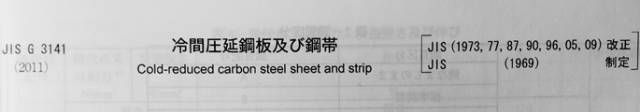

SPCC is derived from JIS, which is the abbreviation of Japanese Industrial Standards.

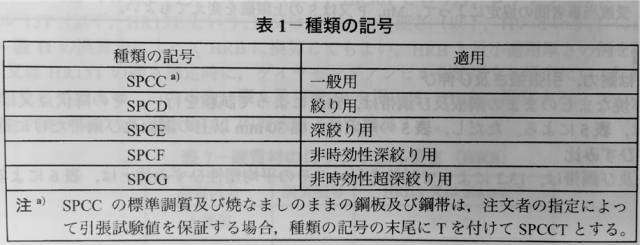

SPCC is included in JIS G 3141. The name of this standard number is "Cold rolled Steel Plate and Steel Strip", which includes five grades: SPCC, SPCD, SPCE, SPCF, SPCG, etc., which are suitable for different application requirements.

Different tempering degrees of SPCC

We often say that a trademark cannot exist alone. The complete explanation is the standard number + trademark + suffix. Of course, this principle is also common to SPCC. Different suffixes in the JIS standard represent different products, the most important of which is the tempering code.

Tempering degree:

A - Annealing only

S——Standard tempering degree

8——1/8 hard

4——1/4 hard

2——1/2 hard

1——hard

What do [annealing only] and [empering degrees] mean?

Standard tempering degree usually refers to annealing + smoothing process. What if it's not flat, then it's [annealed only].

However, since the annealing process of steel plants is now equipped with a smoothing machine, and if it is uneven, the plate shape cannot be guaranteed, so uneven products are rarely seen now, that is, products like SPCC A are rare.

Why are there no requirements for yielding, tensile resistance, and extension?

Because there is no requirement in the JIS standard of SPCC. If you want to ensure the tensile test value, you need to add a T after SPCC to become SPCCT.

What are the 8, 4, 2,1 hard materials in the standard?

If the annealing process is adjusted differently, products with different hardness will be obtained, such as 1/8 hard or 1/4 hard, etc.

Note: It should be noted that the "hard" represented by the suffix 1 is not what we often call "hard rolled coil". It still requires low-temperature annealing.

What are the performance requirements for hard materials?

Everything is within the standards.

For products with different hardness, only the hardness value is guaranteed, and other factors such as yield, tensile strength, elongation, etc., and even the ingredients are not guaranteed.

Tips

1. In trade, we often see that some SPCC brands do not have the suffix S on China’s corporate standard warranty documents. This usually represents the standard tempering degree by default. Due to China's application habits and equipment configuration, annealing + smoothing is a conventional process and will not be specifically explained.

2. Surface condition is also a very important indicator. There are two surface conditions in this standard.

Surface status code

D——pockmarked noodles

B——glossy

Smooth and pitted surfaces are mainly achieved through rollers (smoothing rollers). The roughness of the roll surface is copied to the steel plate during the rolling process. A roller with a rough surface will produce a pitted surface, and a roller with a smooth surface will produce a smooth surface. Smooth and textured surfaces have different effects on processing, and improper selection can lead to processing problems.

3. Finally, we interpret some typical cases of standard columns in warranty documents, such as:

JIS G 3141 2015 SPCC 2 B: 1/2 hard glossy SPCC that meets the requirements of the 2015 version of JIS standards. This product only guarantees hardness, and does not guarantee other components, yield, tensile strength, elongation and other indicators.

Post time: Dec-19-2023