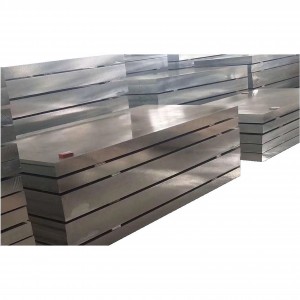

Do you often see cold rolled steel in your life? And how much do you know about cold rolls? This post will provide an in depth answer to what cold rolls are.

Cold rolled steel is steel produced by cold rolling. Cold rolling is the further thinning of No.1 steel plate to a target thickness at room temperature. Compared with hot rolled steel, cold rolled steel thickness is more accurate, and the surface is smooth, beautiful, but also has a variety of superior mechanical properties, especially in terms of processing performance. Because cold rolled steel coils are brittle and hard, they are not very suitable for processing, so usually cold rolled steel plate is required to be annealed, pickled and surface flattened before it is handed over to the customer. The maximum thickness of cold rolled steel is 0.1-8.0MM, such as most of the factory cold rolled steel thickness is 4.5MM or less; the minimum thickness and width are determined according to the equipment capacity of each factory and the market demand.

Processing method: hot rolled steel coils as raw material, after pickling to remove the oxide skin for cold continuous rolling, the finished product is rolled hard coil, due to continuous cold deformation caused by cold hardening of rolled hard coil strength, hardness, toughness and plasticity indicators decline, so the stamping performance will deteriorate, can only be used for simple deformation of the parts. Rolled rolls can be used as raw materials for hot-dip galvanising plants, because hot dip galvanising units are equipped with annealing lines. Rolled hard coil weight is generally 6 ~ 13.5 tonnes, the coil at room temperature, the hot-rolled pickled coil for continuous rolling. The inner diameter is 610mm.

Five Advantages of Cold Rolled Steel Sheet:

1. High dimensional accuracy

The dimensional accuracy of cold rolled steel plate after cold working is higher than that of hot rolled steel plate because cold rolled steel plate is subjected to less thermal deformation during cold working, so its dimensional change is smaller. This makes cold rolled steel plate more suitable for areas requiring high dimensional accuracy, such as automotive manufacturing and machinery manufacturing.

2. Good surface quality

The surface quality of hot rolled steel plate is not as good as cold rolled steel plate, because hot rolled steel plate in the hot rolling process is prone to oxidation, inclusions and thermal cracks. While cold rolled steel plate in the cold process of good surface quality, high flatness, no obvious surface defects. This makes cold rolled steel plate more suitable for use in areas requiring high surface quality, such as electrical appliances manufacturing and construction materials.

3. Stable mechanical properties

After cold-rolled steel plate is cold-worked, its grain size becomes finer and the grain distribution is more uniform. This makes the cold rolled steel plate has better performance stability in the field which requires high mechanical properties, such as aerospace manufacturing and nuclear energy station construction.

4. Low cost

Cold rolled steel production costs are relatively low, because of its production process is simple, do not need like hot rolled steel production process requires a lot of thermal energy consumption. This makes cold rolled steel can be more suitable for cost-sensitive areas.

5. Easy processing

Cold rolled steel plate is easy to process and shape, because in the cold working process, its strength is increased, but the plasticity will not be weakened, so it is easier to process and shape than hot rolled steel plate. This makes cold rolled steel sheet more competitive in a wide range of industrial applications.

Cold rolled steel is widely used in construction, automotive, aerospace, home appliances and other fields.

1. Cold rolled steel in the field of construction applications

A. Building components and steel structure: Cold rolled steel is used in building structure to manufacture channels, angles, tubes and other components; steel trusses, steel beams, steel columns and other steel structures are also commonly used cold rolled steel plates.

B. Roofing and wall panels: Roofing and wall panels made of cold rolled steel are not only beautiful, but also have the characteristics of corrosion prevention, durability, sound insulation and heat insulation.

2. Cold rolled steel in automobile manufacturing applications

A. Automobile body: cold rolled steel is stronger, corrosion-resistant and stronger than hot rolled steel. Therefore, the car body is commonly used cold-rolled steel manufacturing. 2.

B. steering wheel and seat skeleton: cold rolled steel is also commonly used in the manufacture of automotive seat skeleton, steering wheel and other parts, because of its light weight, high strength, fatigue resistance, better safety performance.

3. Cold rolled steel in the field of aerospace applications

A. Aircraft wings, seats and bulkheads: Cold rolled steel is widely used in the manufacture of aerospace vehicles for components such as wings, seats and bulkheads. These components need to be lightweight, strong and corrosion-resistant. 2.

B. Satellite components: Cold rolled steel is also commonly used in the manufacture of satellite components, as satellites need to be ageing-resistant, lightweight and easy to process characteristics.

4. Cold rolled steel in other areas of application

A. Home Appliances: Cold rolled steel made of home appliances shell beautiful, strong, corrosion-resistant, widely used in the manufacture of refrigerators, washing machines, air conditioners and other home appliances.

B. Battery plates: cold rolled steel is also used in the manufacture of lithium batteries and lead-acid battery plates, substrates, with considerable toughness and formability, unabated popularity.

We hope this post has given you a better understanding of cold rolled coils.

Post time: Nov-22-2023