Cold-rolled steel sheets and cold-rolled steel coils are made from hot-rolled steel coils, rolled at room temperature below the recrystallization temperature, including plates and coils. What is delivered into the sheet is called a steel plate, also known as a box or flat plate; the length is very long, and delivered in coils is called steel strip, also known as the coil. They are the same just called differently.

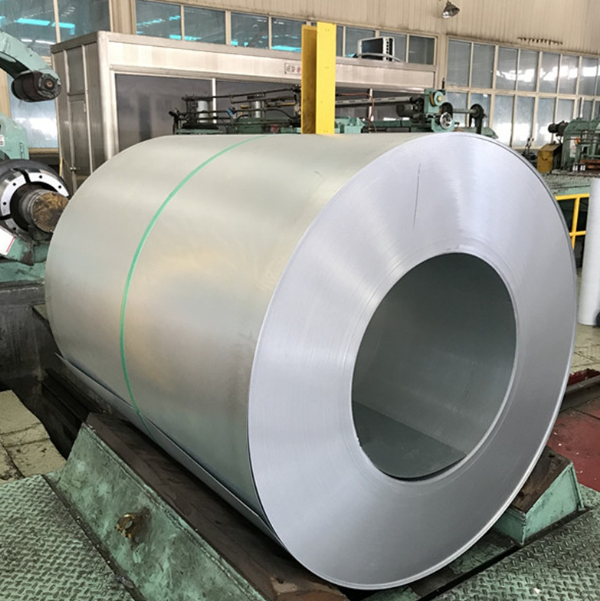

Coil belongs to a kind of plate in steel, is actually long and narrow and supplied in rolls of thin steel plate, rolls and flat plate almost is a cut package.

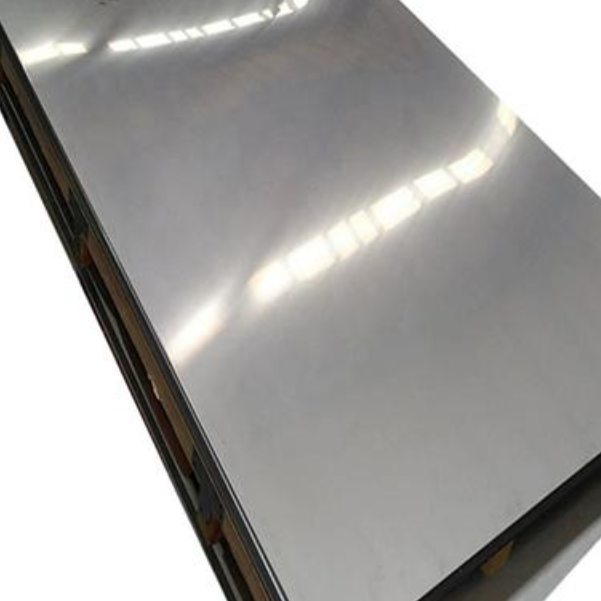

In terms of specifications, the thickness of cold rolled steel sheet in coil is generally 0.2-4mm, width 600-2000mm, and length 1200-6000mm, the specific density depends on the specific specifications of cold rolled steel plate, but there are corresponding standards. Generally speaking, the density of cold rolled carbon steel plate is around 7.85g/cm3.

In the calculation of the following formula: length X width X thickness X density, due to the density of the unit of grams, so generally needs to be the first unit of the above into centimetres, before further comparative calculations.

Steel cold rolled coil (annealed state): hot rolled coil obtained by pickling, cold rolling, hood annealing, levelling, (finishing).

1. Good surface quality

After many times of rolling and heat treatments, the cold rolled coil has a smooth and even surface without obvious scratches, oxidized skin, burrs and other defects, which can meet the high requirements of surface processing needs.

2. High dimensional accuracy

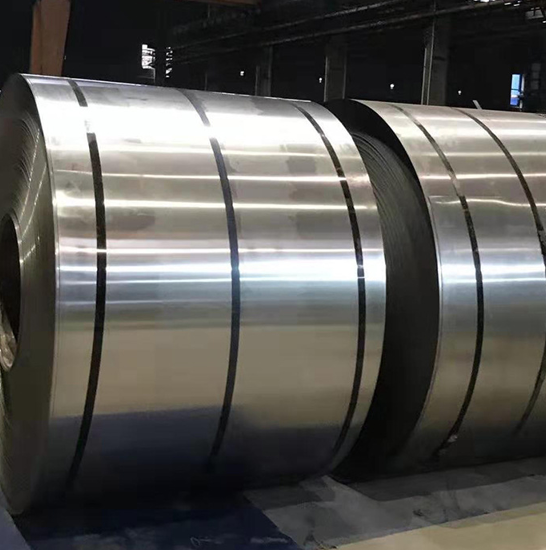

Cold rolled steel is processed through multiple procedures such as precision control of dimensional section, on-line control of plate shape and thickness during rolling, and annealing, etc., and their plate shape and dimensional accuracy can meet the precision requirements of various industries.

3. Stable mechanical properties

Cold rolled coil compared with an ordinary hot rolled coil because it has been rolled and heat-treated many times, its grain is fine, uniform mechanical properties, while having good cold working properties, can obtain higher ductility and toughness so that it has a wider range of applications.

1. Home appliance industry

Cold rolled sheet steel can be used to manufacture shells and structural parts of household appliances such as washing machine shells, refrigerator door panels, air conditioner shells and so on.

2. automobile industry

Cold-rolled carbon steel coil can be used to manufacture body panels, door panels, hoods, luggage racks and other automotive structural parts, with good rigidity and toughness.

3. construction industry

Cold rolled coils can be used to manufacture building panels, steel structures, roof shells and other building materials, with good corrosion and wear resistance.

4. Aerospace industry

Cold-rolled sheets can be used to manufacture aircraft shells, engine parts and other aerospace equipment.

Hot rolled has good plasticity, easy to form, has no internal stress after moulding steel, easy to process the following procedures. Such as the construction of steel bars, used for stamping steel plates, to be machined and heat-treated steel hot-rolled steel. Cold rolled with cold work hardening properties. Due to the cold rolled has better mechanical properties, many direct use of steel are using cold rolled steel. Such as cold-twisted steel bars, cold-rolled steel wire, and cold-rolled steel plate.

Post time: Apr-01-2024