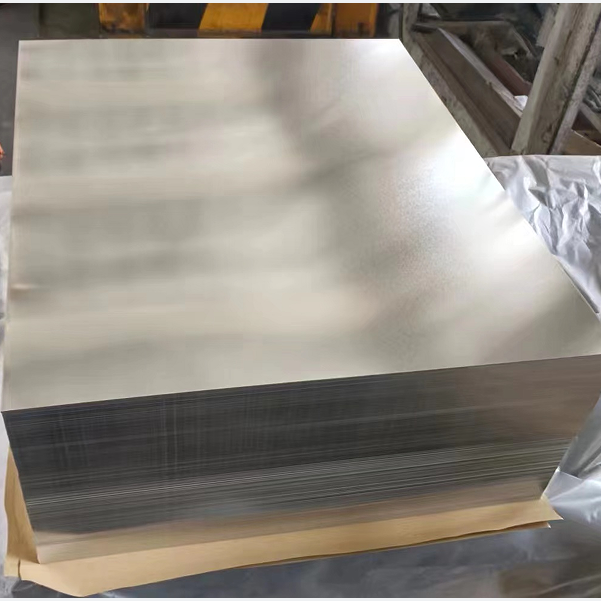

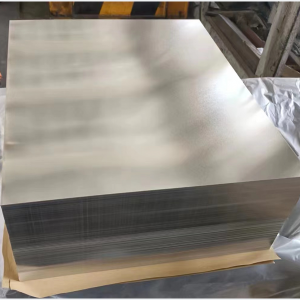

Cold Rolled Steel Tinplate Electrolytic Tinplate Sheet

Electrolytic tinplate is a cold rolled carbon steel plate coated with pure tin on both sides, is a complex production technology, technical, long manufacturing process, high-quality requirements and manufacturing difficult products.

Electrolytic tinplate sheet not only has high strength, good moulding, excellent corrosion resistance, strong welding, bright appearance, etc., but also have good printing colouring, plus the tin layer is non-toxic, so electroplated tin plate is widely used in the food industry and the production of a variety of containers, stamping products, packaging materials and other non-food industry.

Heat-resistant

Recyclable

Easy processing

The tin layer can substantially improve the high-temperature resistance of the tin-plated plate. Considering that many applications require the use of high-temperature environments, tin-plated sheets are therefore widely used.

Cold rolled steel tinplate has superior processability. It can adapt to a variety of moulding processing methods, such as shearing, laminating, moulding and so on. This makes it widely used in light industry.

Tin-plated sheet is non-toxic, non-polluting and has good recyclability. Therefore it is also a good material in terms of environmental protection.

Tinplate electrolytic uses electroplating to reduce the corrosion of steel materials. The tin layer can effectively prevent the steel material from being exposed to air or water oxidation which leads to corrosion.

Application

1. Food packaging field

Tinplate in coil is one of the most widely used food packaging materials. Because the tin layer in the tin-plated plate can play the role of isolation of air, light and water, to ensure that the food does not deteriorate and flavour. In addition, the tin layer can also improve the strength of the packaging to ensure the safety of food.

2. Power industry

Tinplate sheet has an important application in the power industry. It is widely used in the manufacture of capacitors, batteries and other electrical equipment. Because the tin layer can increase the conductivity and corrosion resistance of the tin-plated plate and can improve the appearance of the equipment.

3. Vehicle manufacturing field

Cold rolled steel tinplate sheet is also widely used in vehicle manufacturing. In the automotive industry, tin plate is often used to manufacture body parts, fuel tanks, exhaust pipes and other parts. It can play a role in preventing corrosion, sound insulation and noise reduction.

Growing Trend

The tin-plated steel production process has been standardized, but the single process link is still in continuous improvement and enhancement. The current tin-plated steel plate production process technology development tends to be:

1. The use of steelmaking outside the furnace refining and large-scale continuous casting technology, to get a uniform composition, good quality steel, in order to adapt to a variety of can processing requirements.

2. The use of secondary cold rolling and continuous annealing technology, the production of 0.15 ~ 0.18mm of the original plate, and its high hardness.

3. Pay attention to the pre-plating and post-plating treatment, using a combination of soft-melt treatment, and the production of A-grade, and K-grade tin-plated steel plate.

4. Increase the counterpart supply of coating iron and shaped iron.

5. High-speed and automated inspection and control of operation line, production speed up to 600~760m/min.