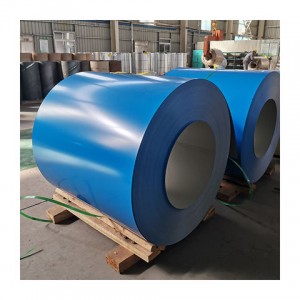

prepainted galvanized color coated steel coil PPGI

Color Prepainted Galvanized Steel Coil

Color Prepainted Galvanized Steel Coil is a type of new building material that rapidly emerged in global market recently,also known as PPGI coils.

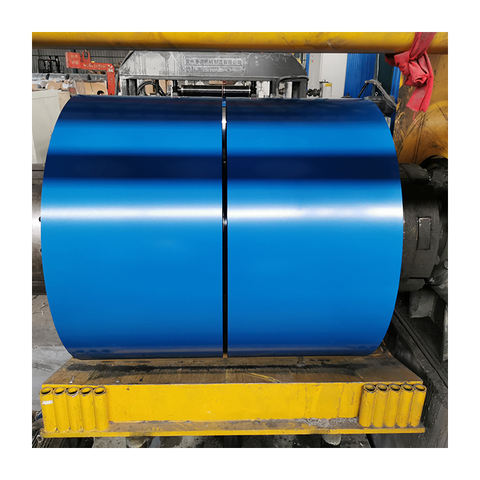

Ppgi prepainted galvanized steel coil is excellent in the performance of decorative, Forming,anticorrossion, strong adhesive force of the coating, as well as keeping the color fresh for a long period of time.

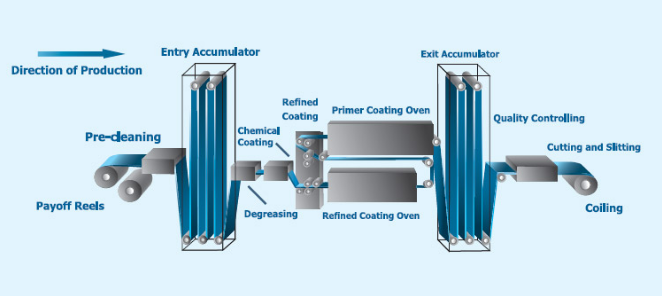

Prepainted galvanized coils are made through the process of chemical pretreatment, preliminary coating and fine coating on the continuous units. The coating seems more even, more stable, and more satisfactory compared to spraying or brushing on the formed metal surface.The product is of pretty colors or patterns when leaving the factory, so it is also called color coated plate. It is prevalently called color coated plate at home, color coat plate or color plate for short.

Hot dip galvanized color coating in addition to zinc protection, the organic coating on the surface also plays a protective isolation, prevent rust.This makes PPGI membranes ideal for architectural designs such as roofing, wall cladding and decorative panels.

PPGI steel coils are also known for their sustainability. Using PPGI membrane helps reduce the need for frequent repainting and maintenance, thereby saving valuable resources. Additionally, these coils are made from galvanized steel, which is a recyclable material. This means that at the end of its useful life, PPGI rolls can be recycled and used to make new products, reducing environmental impact.

As color coated plate can yield prominent economic effects, substituting wood by steel, efficient in construction, energy saving, environmental friendly, it serves as the ideal material for manufacturing building board nowadays.

| Standard | AiSi, ASTM, bs, DIN, GB, JIS |

| Coil thickness | 0.18-0.8mm 2/2(front face double coated/bottom face double coated) |

| Coil width | 800-1250mm |

| Coating structure | 1/2(Front face double coated /bottom face double coated) |

| Coil inner diameter | 508mm&610mm 1/1(front face double coated/bottom face double coated) |

| Coil outer diameter | 800-1500mm |

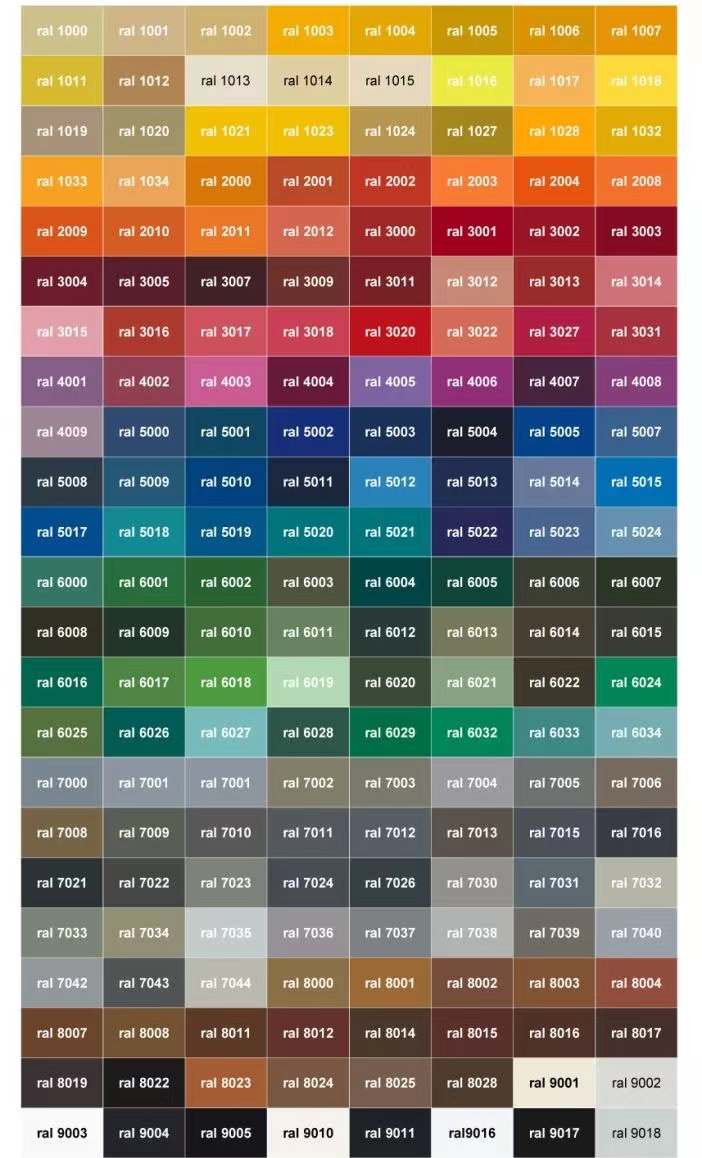

| Color | can be determined as customers require |

| Coil weight | 3-6mt |

| Film thickness | 25-30 microm |

| Surface Treatment | galvanized, aluminum, colour coated |

| Technique | Cold Rolled |

| Tolerance | standard |

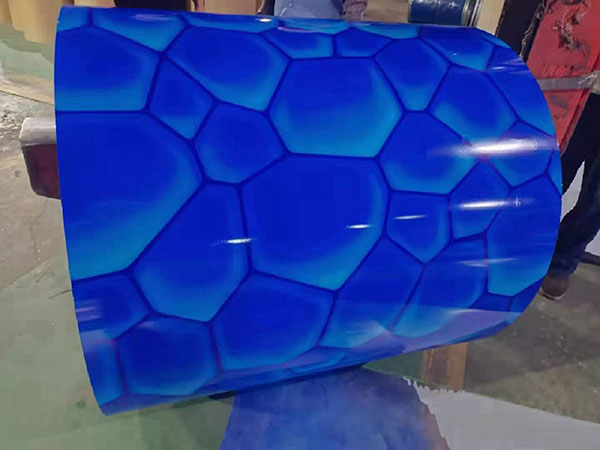

Color options range from vibrant reds and blues to subtle earthy tones.

This allows architects and designers to unleash their creativity and create visually stunning structures.

Application

1. Further making utensil.

2. Solar reflective film.

3. The appearance of the building.

4. Interior decoration: ceilings, walls, etc.

5. Furniture cabinets.

6. Elevator decration.

7. Decorated inside and outside of the car.

8. Household appliances, refrigerators, audio equipments, etc.

Inside: Anti-rust paper, plastic.

Outside: Steel inner and outside guard board, Circle Iron guard board for both side, outside iron guard board, 3 Radical Strapping and 3 Latitude Strapping.

We can also pack according to your requirement.