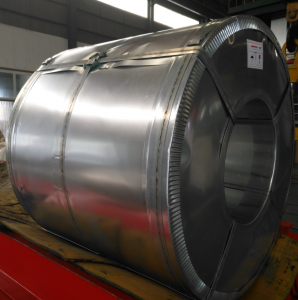

HOT DIPPED GALVANIZED STEEL COIL SGHC

HOT DIPPED GALVANIZED STEEL COIL SGHC

SGHC: S- Steel G- Galvanized

H- hot hot rolled fourth C- Common grade,

meaning hot dipped galvanized coil.

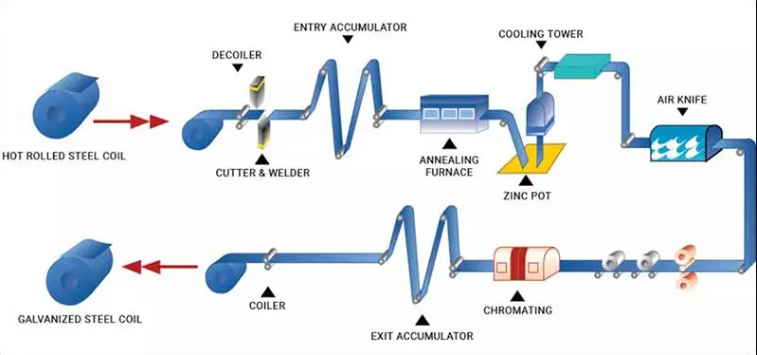

Hot dip galvanizing reacts molten metal with an iron matrix to produce an alloy layer, thereby combining the matrix and the coating. Hot-dip galvanizing is to pickle the steel parts first. In order to remove the iron oxide on the surface of the steel parts, after pickling, they are cleaned in an aqueous solution of ammonium chloride or zinc chloride or a mixed aqueous solution of ammonium chloride and zinc chloride. , and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life.

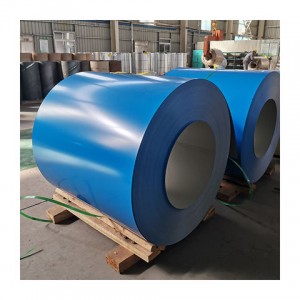

We have been providing you with china hot dipped galvanized steel coils for a long time, we are hot dipped galvanized steel coils suppliers.

Advantage

1. Low processing cost: The anti-rust cost of hot-dip galvanizing is lower than that of other paints and coatings;

2. Durability: Whether in suburban environments, cities or offshore areas, the standard hot-dip galvanized anti-rust layer has good anti-corrosion effects;

3. Good reliability: The galvanized layer is metallurgically combined with the steel and becomes part of the steel surface, so the durability of the coating is more reliable;

4. The coating has strong toughness: the galvanized layer forms a special metallurgical structure and can withstand mechanical damage during transportation and use;

5. Comprehensive protection: Every part of the plated parts can be galvanized, even in depressions, sharp corners and hidden places, they can be fully protected;

6. Save time and effort: The galvanizing process is faster than other painting construction methods. It can avoid the time required for painting at the construction site after installation, and can also greatly save labor costs during the construction process.

To sum up, hot dipped galvanized steel coil is chosen by many hot dipped galvanized steel coil wholesalers and hot dipped galvanized steel coils manufacturers because of its advantages.

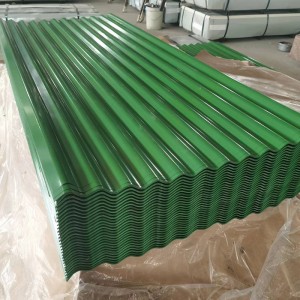

1. Construction field: used in building roofs, wall panels, roof trusses and guardrails, etc., with excellent weather resistance and corrosion resistance.

2. Home appliances: used in refrigerators, freezers, washing machines and other home appliances. It has excellent anti-corrosion capabilities and can extend the service life of the products.

3. Automotive industry: Used in body shells, chassis and interior accessories in automobile manufacturing to provide better anti-corrosion protection and strength support.

4. Electric power industry: used in power facilities such as transmission towers and telephone poles. It has anti-corrosion and weather resistance properties to ensure the safe operation of power equipment.

We can provide you with custom hot dipped galvanized steel coils and we will try our best to meet the specifications you want.We know many hot dipped galvanized steel coil manufacturers and hot dipped galvanized steel coils wholesalers and can ensure quality and on-time delivery. What are you waiting for? Contact us now!