Hot Rolled Checkered Plate

Hot Rolled Checkered Plate

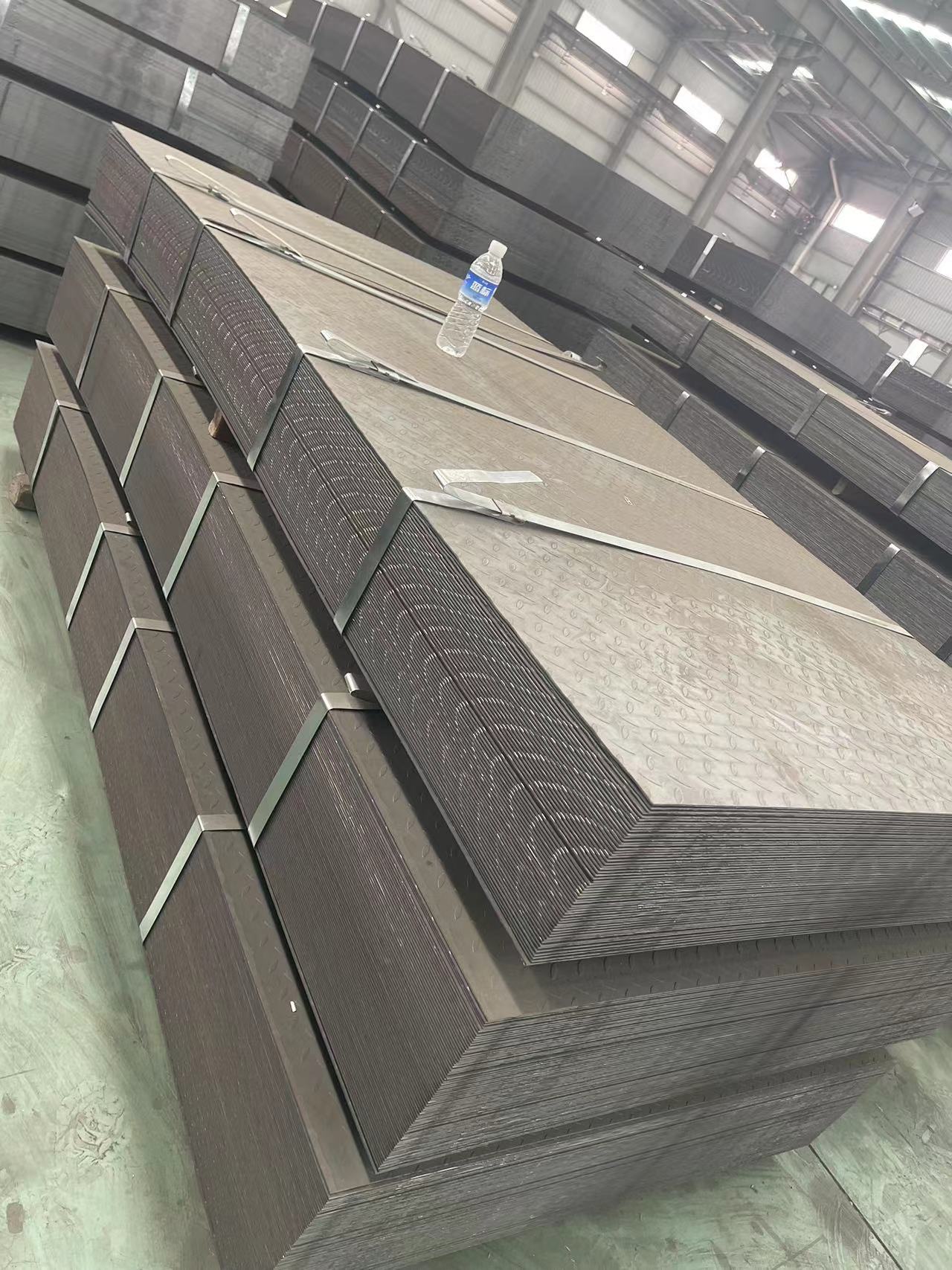

Hot-rolled checkered plates are made of different materials with good strength and plasticity.

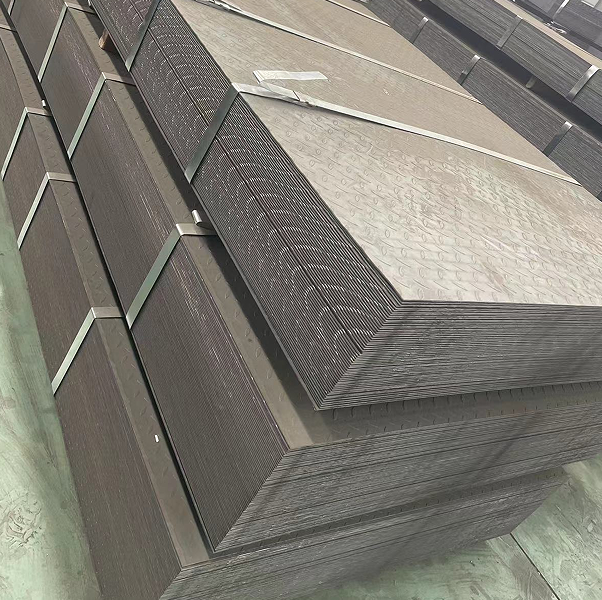

The specification of chequered plate usually refers to the length, width and thickness. Common specifications include 1000mm x 500mm x 2mm, 1250mm x 600mm x 3mm, etc. We can also customize different specifications of patterned steel plates according to user requirements.

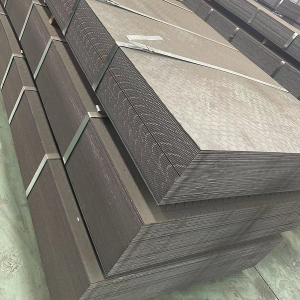

There are many kinds of pattern styles of chequered sheets, such as diamond shapes, lentil shapes, round bean shapes and so on.

Different shapes of patterns have different decorative effects and application scenarios, and users can choose the suitable pattern style according to their needs.

Good anti-slip performance: As the surface of hot rolled checkered plate has an uneven pattern, it can increase the coefficient of friction and improve the anti-slip performance, preventing objects from sliding or slipping on the steel plate.

Decorative: Patterned hot rolled carbon steel plate has a beautiful surface, which can be used as a decorative material to enhance the appearance of buildings and furniture.

Excellent material: Patterned steel plate is made of high-quality steel with good strength, toughness and corrosion resistance, which can meet the needs of different occasions.

Strong customizability: Patterned hot rolled carbon steel sheet can be customized according to actual needs, including specifications, size, material pattern, etc., which is convenient for customers to choose and use according to their own needs.

Construction field: Patterned hot rolled steel plate is widely used in the construction field, such as roofs, walls, floors staircases, etc. It can play the role of decoration and anti-skid.

Automobile field: Patterned steel plate is widely used in automobile manufacturing, such as car bodies, chassis seats, etc. It can improve the load-bearing capacity and anti-skid performance of automobiles.

Furniture: Patterned hot rolled steel sheet is also widely used in furniture manufacturing, such as coffee tables, dining tables chairs, etc., which can enhance the aesthetics and durability of furniture.

Electrical appliances field: In the manufacture of electrical appliances, patterned steel plate is also widely used, such as the shell and internal structural parts of washing machines, refrigerators and air conditioners.

Mechanical field: In mechanical manufacturing, patterned steel plates can be used in the shell and internal structural parts of various equipment to improve the load-bearing capacity and stability of the equipments.

In conclusion, as a common steel material, patterned steel plate has a wide range of applications and market demand. Its excellent anti-slip properties, and decorative and material properties make it one of the indispensable materials in the fields of construction, automobile, furniture, electrical appliances and machinery. With the continuous development of science and technology and the growing social demand, the application prospect of patterned steel plates will be more broad.