SGCC Gi Hot Dipped Galvanized Steel Sheets coil JIS

Hot Dipped Galvanized Steel Sheets

Hot dip galvanizing has the advantages of uniform coating,

strong adhesion, and long service life.

| Grade | SGCC |

| Thickness | 0.1-4mm |

| Width | 500-1250mm |

| Zinc coating | 30-275g/m2 |

| Surface | chromated,un-oiled,dry |

| Spangle | regular,minimized,big spangle,zero spangle |

| Coil weight | 4-12mt |

Galvanizing is an economical and effective antirust method which is often used.Also known as GI (galvanized iron), this type of steel is made by dipping coils of cold rolled or hot rolled steel into a bath of molten zinc, creating a protective layer that prevents corrosion and extends the life of the material. SGCC (Steel Grade Coating Composition) is often used as a quality benchmark for evaluating the efficiency of hot dip galvanized steel coils and sheets.

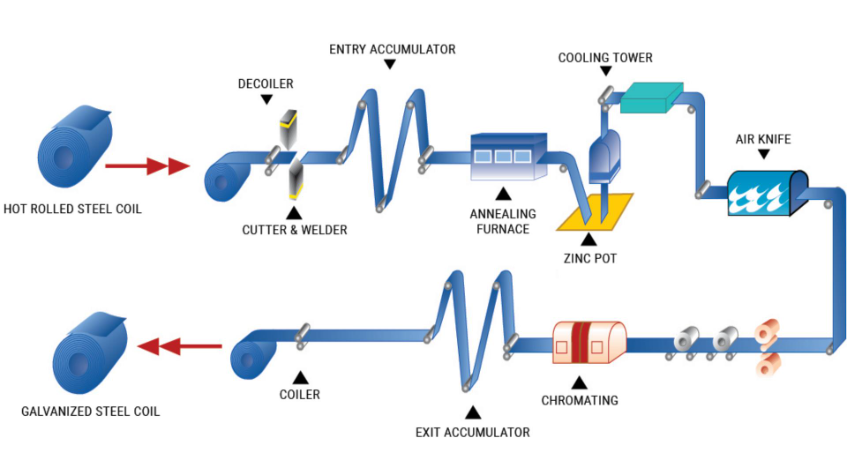

Hot dip galvanizing is to pickle the steel parts first. In order to remove the iron oxide on the surface of the steel parts, after pickling, they are cleaned in an aqueous solution of ammonium chloride or zinc chloride or a mixed aqueous solution of ammonium chloride and zinc chloride. , and then sent into the hot dip plating tank. The so called hot dip plating is a method of immersing a base metal in another low melting point metal in a molten state to form a metal protective film on its surface.

1.Corrosion resistance

2.Wear resistance

3.High temperature strength

4.Tensile strength

5.High aesthetics

6.Simple process

7.Energy saving

1.Petrochemical: Hot-dip galvanizing is often used to protect petrochemical equipment from corrosion, such as pipes, valves, flanges, pumps, etc.

2.Construction field: Hot-dip galvanizing can be used to protect building structures from corrosion, such as steel bars, steel plates, scaffolding, etc.

3.Light industry: Hot-dip galvanizing can be used for various metal products in the light industry, such as pens, hardware, furniture, etc.

4.Aerospace: Hot-dip galvanizing is widely used in the aerospace field to protect aircraft, rockets and other aviation equipment from corrosion.

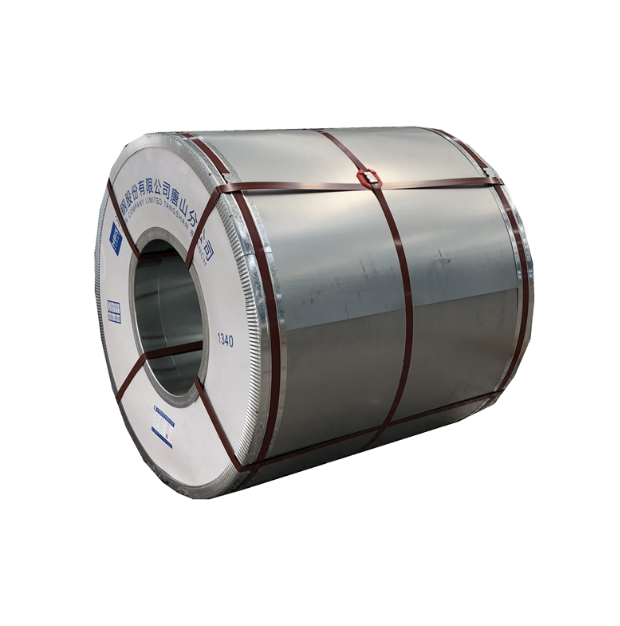

Inside: Anti-rust paper, plastic.

Outside: Steel inner and outside guard board, Circle Iron guard board for both side, outside iron guard board, 3 Radical Strapping and 3 Latitude Strapping.

We can also pack according to your requirement.

Our company has large warehouses all over China, with sufficient inventory and short delivery cycle. With many years of experience in exporting coiled materials, we have standard packaging and Transportation Standards for sheet materials shipping, so as to protect the safety of your goods in shipping in an all-round way. Applicable to container and bulk cargo.

Why choose Lishengda Trading Co?

1. Contract is honored and credit maintained.

2. Competitive price with excellent quality.

3. Professional exporting team.

4.Convenient transportation location.

5. Short shipment period.