Cold rolled seamless steel tube pipe

COLD ROLLED SEAMLESS STEEL PIPE

The raw material of cold worked steel pipes can be hot rolled seamless steel pipes or welded pipes.

The common features of the steel pipe cold working method are high dimensional accuracy and good surface roughness. The production process of a general seamless steel tube can be divided into two types: cold rolling and hot rolling.In appearance, cold rolled seamless steel pipes are shorter than hot rolled seamless steel tubes. The surface is not too rough, and the calibre does not have too many burrs.

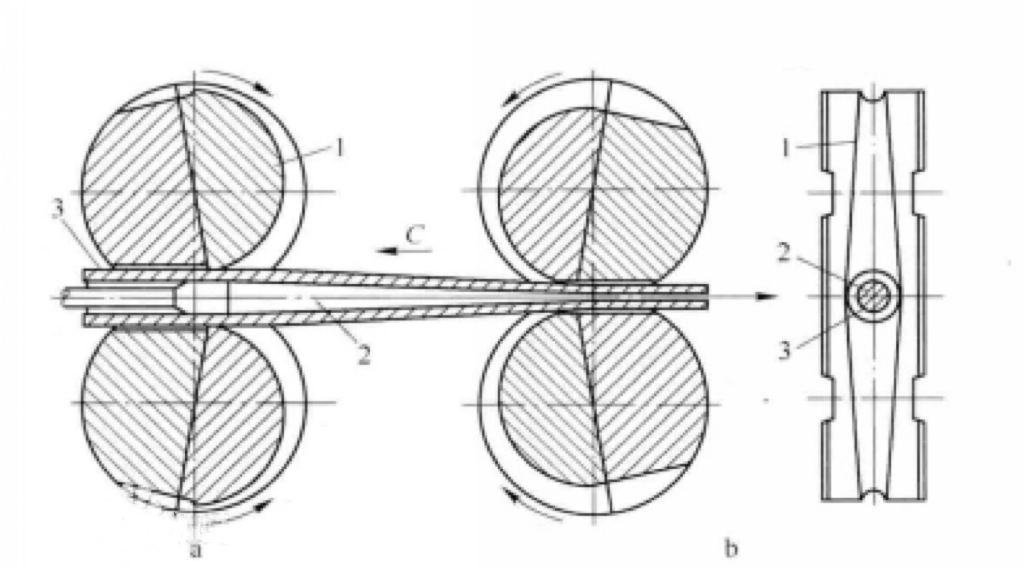

The main advantage of rolled steel pipes is the large section reduction rate, especially the strong wall reduction ability.At present, periodic cold rolled pipe machines are mostly used in the production of cold rolled pipes. The reciprocating movement of the frame drives the rolling of the steel pipe, and the variable cross section profile is used to compress the rolled piece to achieve the purpose of diameter and wall reduction.

Advantages: fast forming speed, high output, and does not damage the coating. It can be made into a variety of cross-sectional forms to adapt to the needs of use conditions; cold rolling can cause large plastic deformation of steel, thereby improving the yield of the steel.

The manufacturing process of cold rolled seamless steel pipe is more delicate and complex than that of ordinary steel pipe, which improves the precision of the steel pipe. The equipment and process used in the manufacturing of cold rolled seamless steel pipe is also more complex, which can ensure the precision and quality of the steel pipe. Therefore, cold rolled seamless steel pipe can meet the needs of some high-precision processing and application occasions.

The surface of cold rolled seamless steel pipe is smooth and there is no oxidized layer, which is not prone to corrosion and other problems. Its surface quality is better than ordinary steel pipe, which can meet the needs of some special occasions. The surface smoothness of cold rolled seamless steel pipe can also reduce the resistance of liquids and gases in the pipeline and promote fluid transmission.

Application:

1. Machinery manufacturing field

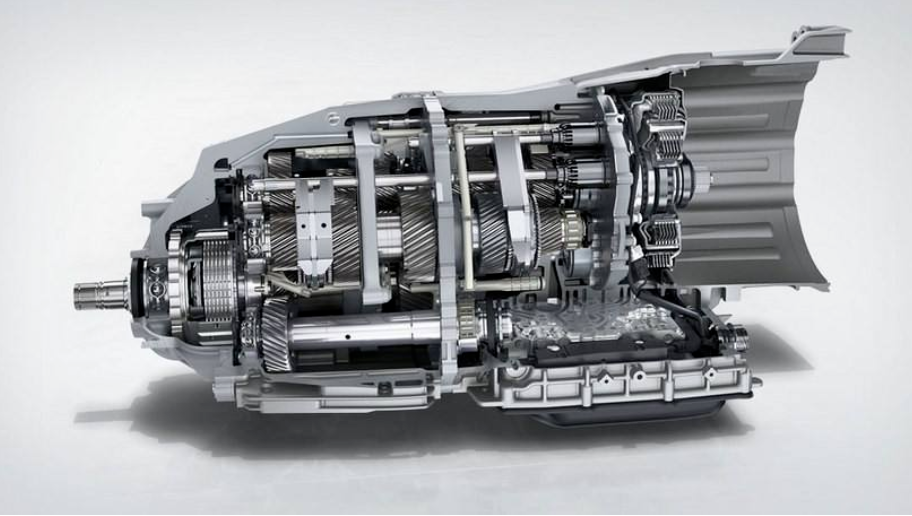

Used to manufacture tires, engines, shock absorbers, transmissions, drive shafts, crankshafts, balance shafts and other mechanical parts to meet the needs of different fields.

2. Automobile manufacturing field

It is suitable for manufacturing lightweight body, chassis, engine and other parts. It has the characteristics of high strength, good durability and corrosion resistance. It can improve the quality and reliability of automobile parts and make the vehicle safer, more stable and environmentally friendly.

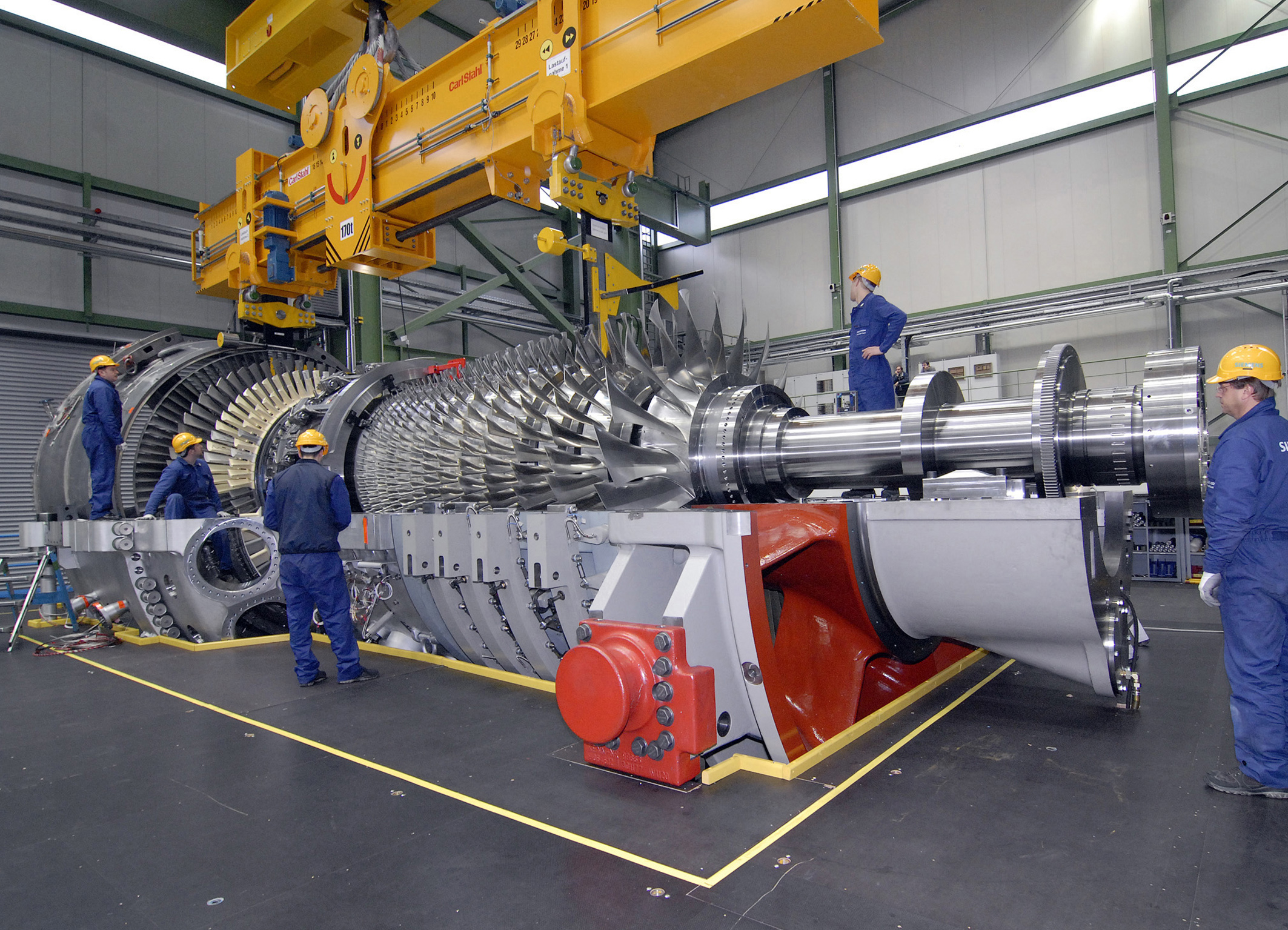

3. Aerospace field

Due to its excellent high-temperature strength and corrosion resistance, it can meet the requirements of aircraft engines, gas turbines, high-temperature and high-pressure vessels and other components, and is used to improve the safety, reliability and performance of aerospace equipment.

4. Petrochemical field

Cold rolled seamless steel pipes are widely used in pipeline transportation systems, which can improve the safety and reliability of petrochemical transportation systems.

We can not only provide you with steel pipes, but also all other steel products, such as hot rolled steel coils, cold rolled steel coils, galvanized steel coils, wire rods, etc. Don't hesitate any longer and contact me.You can leave a message online or send an email.