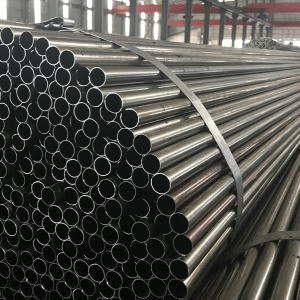

Hot rolled seamless steel tube pipe

Hot Rolled Seamless Steel Pipe

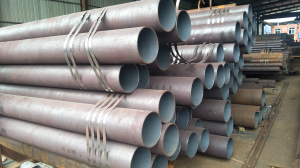

Hot rolled seamless steel tubes are generally produced on automatic pipe rolling units.

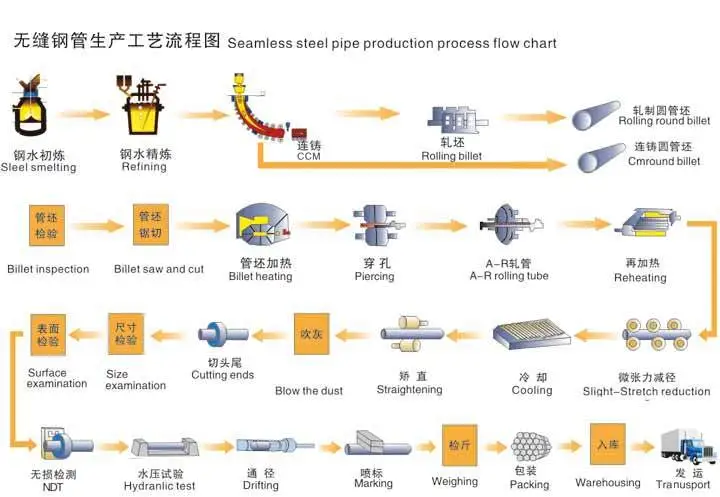

The solid tube blank is inspected and surface defects are removed, cut into the required length, centered on the perforated end of the tube blank, and then sent to the heating furnace for heating and piercing on the punching machine. It continues to rotate and advance during piercing holes. Under the influence of the rollers and the end, the tube blank is hollow gradually, which is called gross pipe. Then it is sent to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is evened by the leveling machine, and the diameter is determined by the sizing machine to meet the specification requirements. The use of continuous pipe rolling units to produce hot rolled seamless steel pipes is a more advanced method.

Hot rolled seamless steel pipe: round tube blank → heating → perforation → three-roll cross rolling, continuous rolling or extrusion → tube removal → sizing (or diameter reduction) → cooling → billet tube → straightening → hydraulic pressure test (or flaw detection )→mark→warehouse

Types And Standards

1.Seamless steel pipe for structural use (GBT8162-1999). Mainly used for general structures and mechanical structures. Its representative materials (grades): carbon steel, No. 20, and No. 45 steel; alloy steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, etc.

2.Seamless steel pipes for transporting fluids (GBT8163-1999). Mainly used for conveying fluid pipelines in engineering and large-scale equipment. Representative materials (grades) are 20, Q345, etc.

3.Seamless steel pipes for low and medium pressure boilers (GB3087-1999) are used to manufacture superheated steam pipes, boiling water pipes for low and medium pressure boilers of various structures, superheated steam pipes, large smoke pipes, small smoke pipes and arch bricks for locomotive boilers. High-quality carbon structural steel hot-rolled and cold-drawn (rolled) seamless steel pipes for pipes. The representative materials are No. 10 and No. 20 steel.

4.Seamless steel pipes for high-pressure boilers (GB5310-1995) are high-quality carbon steel, alloy steel and stainless heat-resistant steel seamless steel pipes used for the heating surfaces of water tube boilers with high pressures and above. Representative materials are 20G, 12Cr1MoVG, 15CrMoG, etc.

5.Seamless steel pipes for high-pressure fertilizer equipment (GB1479-2000) are high-quality carbon structural steel and alloy steel seamless steel pipes suitable for chemical equipment and pipelines with working temperatures of -40~400℃ and working pressures of 10~30Ma. Representative materials are 20, 16Mn, 12CrMo, 12Cr2Mo, etc.

6.Seamless steel pipe for petroleum cracking (GB9948-1988). Mainly used in boilers, heat exchangers and pipelines for transporting fluids in petroleum refineries. Its representative materials are 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb, etc.

7.Steel pipes for geological drilling (YB235-70) are steel pipes used by geological departments for core drilling. They can be divided into drill pipes, drill collars, core pipes, casings and sedimentation pipes according to their uses.

8.Seamless steel pipe for diamond core drilling (GB3423-82) is a seamless steel pipe used for drill pipe, core rod and casing for diamond core drilling.

9.Oil drilling pipe (YB528-65) is a seamless steel pipe with internal or external thickening at both ends used for oil drilling. There are two types of steel pipes: wired and unthreaded. Threaded pipes are connected with joints, while non-threaded pipes are connected with tool joints by butt welding.

10.Carbon Steel Sheet Coil and carbon-manganese steel seamless steel pipes for ships (GB5312-1999) are carbon steel seamless steel pipes used in manufacturing ships’ Class I pressure-resistant piping systems, Class II pressure-resistant piping systems, boilers and superheaters. The working temperature of thecarbon steel seamless steel pipe wall does not exceed 450°C, and the working temperature of the alloy steel seamless steel pipe wall exceeds 450°C. Representative materials are 360, 410, 460 steel grades, etc.

11.Seamless steel pipe for automobile half-shaft casing (GB3088-82) is a high-quality carbon structural steel and alloy structural steel hot-rolled seamless steel pipe used for manufacturing automobile half-shaft casings and drive axle housing shaft tubes.

12.High-pressure oil pipe for diesel engine (GB3093-86) is a cold-drawn seamless steel pipe used to manufacture high-pressure pipes for diesel engine injection systems.

13.Stainless steel seamless steel pipe for structural use (GB/T14975-1994) is a hot-rolled stainless steel ( extruded, expanded) and cold drawn (rolled) seamless steel pipes.

14.Stainless steel seamless steel pipes for fluid transportation (GB/T14976-1994) are hot-rolled (extruded, expanded) and cold-drawn (rolled) seamless steel pipes made of stainless steel used to transport fluids.

15.Seamless steel pipes for gas cylinders (GB18248-2000). Mainly used to make various gas and hydraulic cylinders. Its representative materials are 37Mn, 34Mn2V, 35CrMo, etc.

Seamless steel pipes can destroy the casting structure of the steel ingot, refine the grains of the steel, and eliminate defects in the microstructure, thereby making the steel structure dense and improving the mechanical properties. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; bubbles, cracks and looseness formed during pouring can also be welded under the action of high temperature and pressure.

As a seamless steel pipe among hollow steel pipes, it has the following uses:

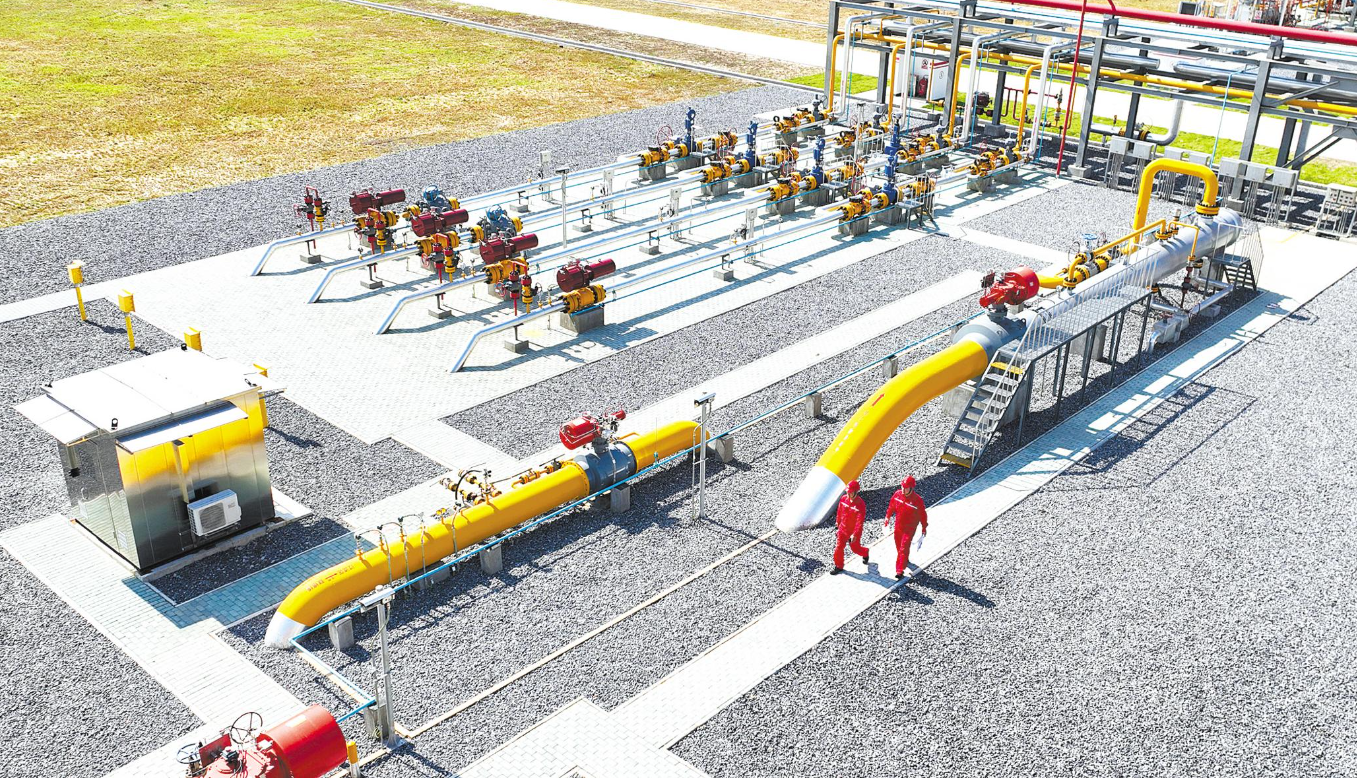

1.Oil and gas: Hot rolled seamless steel pipes are widely used in transportation pipelines in the fields of oil, natural gas, coal gas, etc., such as oil well drill pipes, oil pipes, oil casings, underground gas production pipelines, etc.

2.Water supply and gas supply: Hot rolled seamless steel pipes are suitable for transportation pipelines in various water supply and gas supply systems, transporting compressed air, steam and other fields.

3.Chemical industry: hot rolled seamless steel pipes are suitable for various chemical equipment, reactors, transportation pipelines, pipe clamps and other fields.

4.Shipbuilding and aviation: Hot rolled seamless steel pipes are widely used in engine rooms, propulsion systems and other parts in shipbuilding, aviation and other fields.

5.Other uses: Hot rolled seamless steel pipes are also suitable for anti-corrosion coatings, construction fields, machinery manufacturing, auto parts, etc.

There are three types of steel pipe packaging: bundling, boxing, oiled bundling or oiled boxing.Also according to customer requirements.

Our company has large warehouses all over China, with sufficient inventory and short delivery cycle. With many years of experience in exporting coiled materials, we have standard packaging and Transportation Standards for sheet materials shipping, so as to protect the safety of your goods in shipping in an all-round way. Applicable to container and bulk cargo.

Why choose Lishengda Trading Co?

1. Contract is honored and credit maintained.

2. Competitive price with excellent quality.

3. Professional exporting team.

4.Convenient transportation location.

5. Short shipment period.