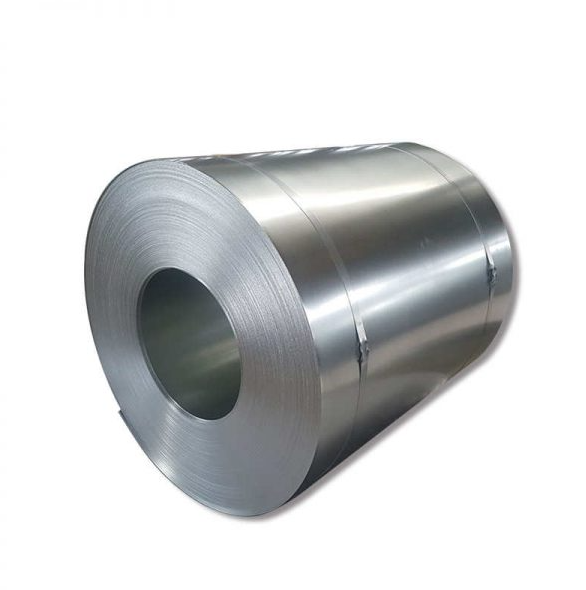

Dx51d Hot Dipped Galvanized Steel Coil sheet

Galvanized Steel Coil Dx51d

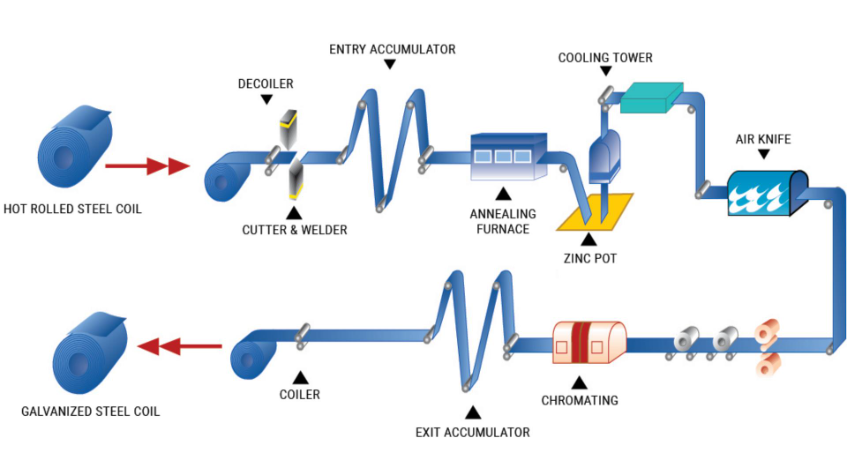

In DX51D, D represents the bending and forming grade of galvanized sheet, and 51 represents the serial number of the steel grade, which mainly uses low-carbon steel as its basic material.

This method, often used in practice, is economical and effective for anti-corrosion: Galvanized steel coil Dx51d.

| Grade | Dx51d |

| Thickness | 0.1-4mm |

| Width | 500-1250mm |

| Zinc coating | 30-275g/m2 |

| Surface | chromate,un-oiled, dry |

| Spangle | regular, minimized,big spangle, zero spangle |

| Coil weight | 4-12mt |

To conclude, hot-dipped galvanized steel sheets and coils, such as the highly sought-after Dx51d grade, are invaluable in today's industrial landscape. Offering exceptional corrosion resistance, durability, and versatility, they have become the go-to choice for various applications. Their ability to withstand harsh environments, maintain structural integrity, and be easily fabricated make them a reliable and cost-effective material for countless industries. Whether it be automotive manufacturing, construction projects, or agricultural equipment, hot-dipped galvanized steel sheets and coils are at the forefront of innovation and progress.

This kind of hot-dipped galvanized steel sheet is also made by the hot dip method, but it is heated to about 500°C immediately after coming out of the tank to form an alloy film of zinc and iron. This particular type of galvanized steel coil boasts excellent paint adhesion and weldability.

(1) Excellent corrosion resistance and long service life;

(2) Good processability and can meet different processing requirements;

(3) Excellent mechanical properties, with good mechanical properties such as tensile strength, compression resistance, and bending resistance;

(4) Excellent appearance performance, able to meet different appearance requirements.

Application

Dx51d steel plate is mainly used in construction, home appliances, transportation, machinery manufacturing, power equipment and other fields. Specific applications are as follows:

(1) Construction field: used in the manufacturing of building roofs, walls, roof trusses, doors and windows, etc.;

(2) Home appliance field: used in the manufacturing of refrigerators, washing machines, air conditioners, televisions and other home appliances;

(3) Transportation field: used in the manufacturing of cars, trains, ships and other means of transportation;

(4) Machinery manufacturing field: used to manufacture machine tools, tools, moulds and other mechanical equipment;

(5) Power equipment field: used to manufacture transformers, generators, cables and other power equipment.

Inside: Anti-rust paper, plastic.

Outside: There is a steel inner and outer guard board, a circle iron guard board on both sides, an outer iron guard board, three radial strappings and three lateral strappings.