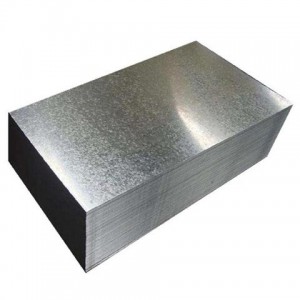

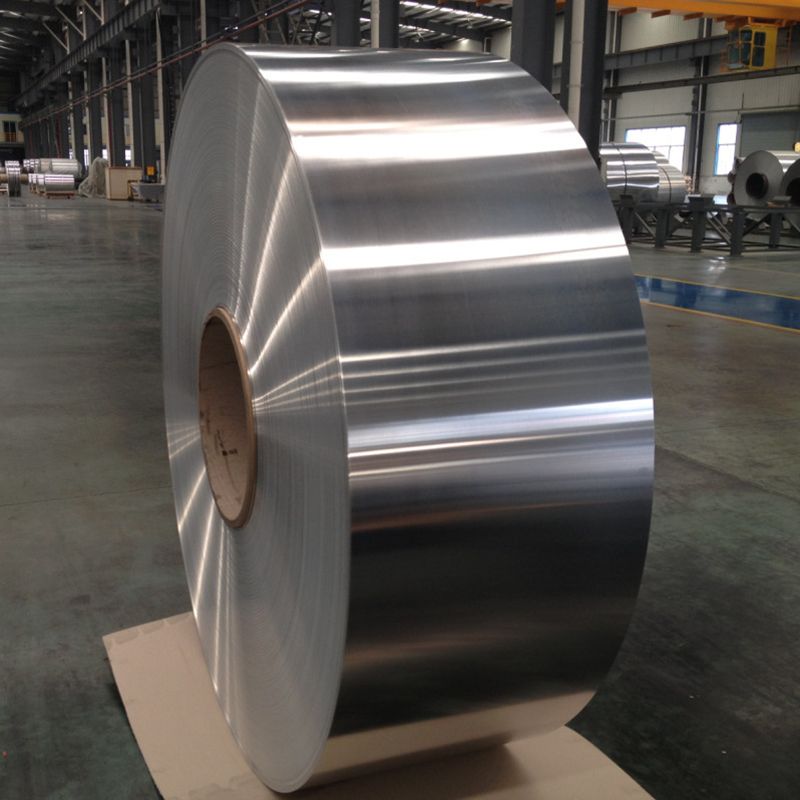

PRIME HOT DIPPED GALVANIZED STEEL SHEET IN COILS

Prime Hot Dipped Galvanized Steel Coils

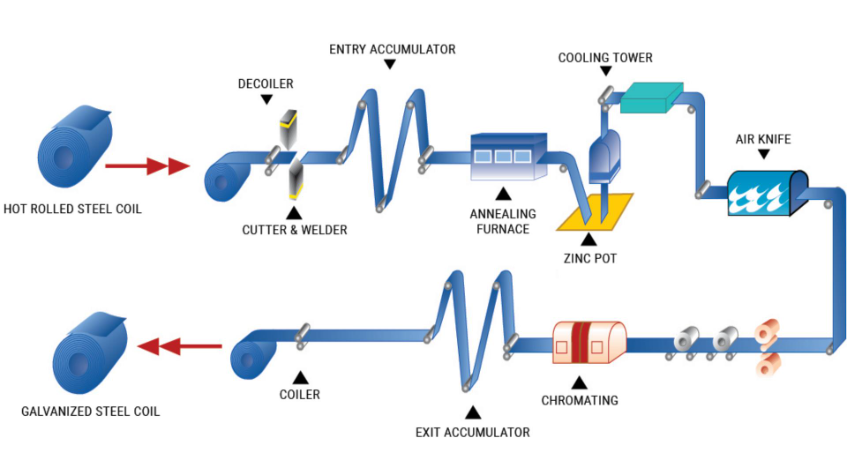

Hot dipped galvanized steel coils are processes whereby molten metal reacts

with an iron substrate to produce an alloy layer,

thus combining both the substrate and the coating.

| standards | GB/JIS/ASTM |

| thickness | 0.1-4.0mm |

| width | 500-1250mm |

| zinc coating | 30-275g/m2 |

| surface | chromated/un-oiled/dry |

| spangle | regular/minimized/big spangle/zero spangle |

| weight | 4-12mt |

Hot dipped galvanized steel sheets are done by first pickling the steel fabricated parts, in order to remove the iron oxide on the surface of the steel fabricated parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tanks, and then it is sent to hot dip galvanising tanks. In the atmosphere, zinc is much more resistant to corrosion than steel, and under normal conditions zinc is 25 times more resistant to corrosion than steel. Therefore hot dip galvanising has a strong corrosion resistance.Prime hot dipped galvanized steel sheet in coils have the advantages of uniform coating, strong adhesion and long service life.

Hot dip galvanising originated at the end of the 19th century, when it was mainly used to protect iron products from corrosion. With the development of technology, hot dip galvanising has gradually become an important metal surface treatment process and is widely used in various fields. Prime hot dipped galvanized steel coils advantages are as follows:

1. Corrosion resistance: Zinc is the second most important element after aluminium and has excellent corrosion resistance. In marine environments, industrial atmospheres, soils and corrosive media, the zinc layer effectively protects products from corrosion.

2. Abrasion resistance: The high hardness of the galvanised layer resists wear and tear on the steel surface. Therefore, hot dipped galvanized steel coil has a good service life in mining and chemical industries.

3. High-temperature strength: The hot dip galvanised layer can still maintain high strength and hardness at high temperatures, which is conducive to improving the service life of the products in high temperature environments.

4. Tensile strength: the zinc layer can significantly improve the tensile strength of the products, which is conducive to improving the stability of the products under the action of external forces.

5. High aesthetics: the zinc layer is silver white with good gloss, making hot dipped galvanized steel coil in construction, home appliances and other fields with high decorative value.

6. Simple process: hot dip galvanising process is relatively simple, with short production cycle and low cost.

7. Environmentally friendly and energy-saving: The hot dip galvanising process produces less waste and has a low impact on the environment, making it an environmentally friendly surface treatment method. In addition, the hot dip galvanising production process does not need to consume a lot of energy, which is conducive to reducing energy consumption.

Based on these advantages of prime hot dipped galvanized steel coils, it has become one of the popular choices for hot dipped galvanized steel coil manufacturer, hot dipped galvanized steel coil wholesaler and hot dipped galvanized steel coils supplier.

Prime hot dipped galvanized steel coil is widely used by hot dipped galvanized steel coils manufacturer and hot dipped galvanized steel coils wholesaler in the following areas:

1. Petrochemical: prime hot dipped galvanized steel sheet is commonly used to protect petrochemical equipment from corrosion, such as pipes, valves, flanges, pumps etc.

2. construction field: prime hot dipped galvanized steel sheet can be used to protect building structures from corrosion, such as steel bars, steel plates, scaffolding, etc.

3. Light industry: prime hot dipped galvanized steel sheet can be used for various metal products in light industry, such as pens, hardware, furniture, etc.

4. Aerospace: prime hot dipped galvanized steel sheet is widely used in the aerospace industry to protect aircraft, rockets and other aviation equipment from corrosion.

Status Of Hot Dip Galvanising Industry In China

China's hot dip galvanising industry started in the 1950s, and after years of development, it has become the world's largest hot dip galvanising producer. At present, china hot dipped galvanized steel coils are mainly located in Hebei, Jiangsu and Shandong, with the hot dip galvanising capacity in Hebei province accounting for nearly half of the country's total capacity. In recent years, with the strengthening of national policies on environmental protection, China's hot dip galvanising industry is gradually developing in the direction of green and environmental protection. Many enterprises have started to introduce advanced production processes and technologies to improve product quality and reduce energy consumption.

1. Green development: As environmental awareness increases, the future hot dip galvanising industry will focus more on green development. Enterprises will increase investment in environmental protection technology and equipment, improve resource efficiency and reduce pollutant emissions.

2. Intelligent manufacturing: with the development of intelligent manufacturing technology, the future hot dip galvanising industry will achieve intelligent manufacturing. Through the introduction of robots, automated production lines and other advanced equipment to improve production efficiency and reduce labour costs.

3. Combination of industry, academia and research: In order to adapt to changes in market demand, the future hot dip galvanising industry will strengthen cooperation with universities and research institutes to jointly develop new products and technologies and improve the core competitiveness of enterprises.

After the introduction of this article, do you have a better understanding of prime hot dipped galvanized steel coils? We can provide you with prime hot dipped galvanized steel sheet in coil factory and even custom hot dipped galvanized steel coils to meet your needs as much as possible. How about it? Want to know more about us? Looking forward to your emails.