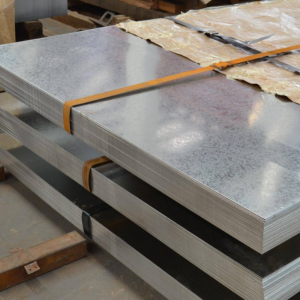

Galvanized Steel Strip DX51D

Galvanized Steel Strip

DX51D hot dip galvanized steel strip represents not only an advancement in steel but also a change in the times and the future trends of manufacturing.

The role of the zinc coating should not be underestimated, it is like a loyal guard, trying its best to protect the inner steel from attack. The strength of this galvanized steel strip is like a fiercer bucket ten, in all kinds of severe environments can maintain the rigidity and toughness of steel. Good formability, jointing, and ductility make it easy to use and handle!

The galvanized strip is strip with a zinc coating on the surface.

Its substrate can be either a hot-rolled or cold-rolled strip.

There are two main purposes: anti-corrosion (to extend the service life) and aesthetic.

General galvanized steel strip processing process:

(1) pickling (to remove iron oxide on the surface of the strip)

2) cold rolling (rolling thin, improving wall thickness tolerance, surface finish)

3) galvanized (in the iron substrate to form a zinc-iron alloy layer + zinc layer, anti-corrosion, beautiful)

4) Delivery (part of the product after slitting and slitting, to the net edge state delivery)

Special Note: Some of the thicker galvanized steel strips (such as the thickness of 2.5mm or more), do not need cold rolling, or pickling directly after galvanizing, called pickling straight plating, this mainly depends on the downstream product requirements.

The galvanized steel strip is generally used to make steel pipes, such as greenhouse pipes, drinking water pipes, heating pipes, and gas transmission pipes; can also be used in construction, light industry, automobile, agriculture, livestock and fisheries, and commercial industries.

Among them, the construction industry is mainly used to manufacture corrosion-resistant industrial and civil building roof panels, roof grills, etc.; the light industry with its manufacturing appliances shell, civil chimneys, kitchen utensils, etc., the automotive industry is mainly used for the manufacture of corrosion-resistant parts of the car and so on.